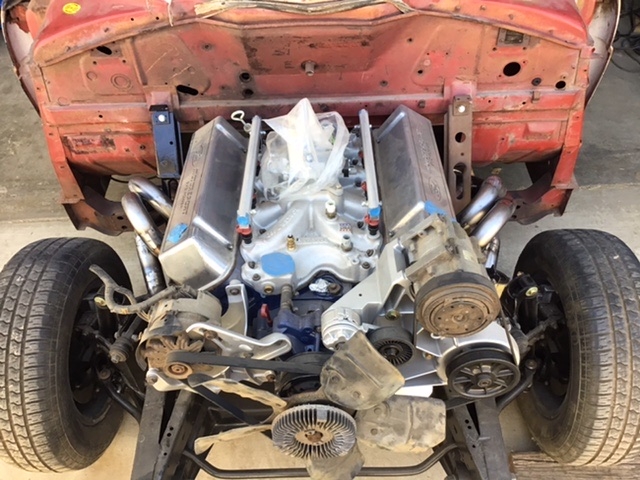

Jag IFS in my Hudson

Comments

-

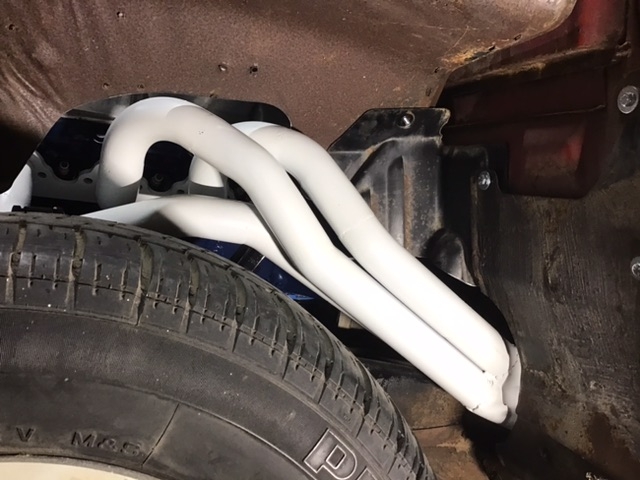

Can't really tell from the picture, but the tire to header distance looks pretty tight.

I think if I had your skills, i would have tried to modify the right frame rail to clear the exhaust manifold. Even as a kid I learned to hate the exhaust exit next to my ear and I was running an OEM type muffler.0 -

Thank you for the kind words, Fred. There is about four inches between the tire and the closest header tube to the front tire, and I will be using a slightly smaller diameter tire when it's all said and done. I think the headers are going to be better in the long run, and I was up for the challenge. It was good practice for making an intake and exhaust for a future Hornet engine.0

-

Very cool. Are you gas welding everything?0

-

At this point, yes.bent metal said:Very cool. Are you gas welding everything?0 -

I’ve started on the other side. The third tube is going to be a challenge. It is almost perfectly centered on the firewall strut. I’m not sure yet, how I am going to address that.0

I’ve started on the other side. The third tube is going to be a challenge. It is almost perfectly centered on the firewall strut. I’m not sure yet, how I am going to address that.0 -

Why not make a tubular strut, or cut that one and notch it with reinforcement.0

-

That's probably what will happen. I will figure that out once the tubes are all done.0

-

Progress has been a little slow, but I’m working on the last tube now.0

Progress has been a little slow, but I’m working on the last tube now.0 -

Looks really good.

0

0 -

Good work takes time ---the headers look great! Curious whether you prefer Gas Welding over TIG for this type of work? Seems most folks opt for TIG these days. Personally I've haven't invested the time perfecting how to TIG mainly because I cut my teeth on MIG and Stick (arc) and both have served on everything I've encountered in automotive work thus far.0

-

Something to consider when welding tubing is to gas purge the ID during the welding process with any inert gas, argon being a common choice. Tape one end closed and poke several very small holes in it. A sharpened tungsten from a TIG torch being often used to poke the holes. Tape the hose from the gas source into the other end. The gas pressure should be very low only a pound or two. Bleed the gas in for a bit, the object being to push all the oxygen out of the tubing. Maintain the purge during welding. This is to prevent the ID of the weld & base metal from being oxidized during welding. If oxidized material if left in the ID this can be a location for future corrosion.0

-

I have equipment to arc weld, or gas weld…. Until today. I bought a tig welder today. Now I will be learning a new skill. I hope this doesn’t slow the buil down too much.StepUp said:Good work takes time ---the headers look great! Curious whether you prefer Gas Welding over TIG for this type of work? Seems most folks opt for TIG these days. Personally I've haven't invested the time perfecting how to TIG mainly because I cut my teeth on MIG and Stick (arc) and both have served on everything I've encountered in automotive work thus far. 0

0 -

One of the keys to a good TIG weld is to match the type tungsten to the material being welded. Any reputable welding supply house near you should be able to help with that. I see your torch has a long gas lens. You may find it easier with the tight welds to be made if you have a shorter gas lens.0

-

PS, if you decide to gas purge the ID during welding tape closed the joints not being welded0

-

You will never regret going to TIG. ....finally!

0 -

I’m welding up the tubes and getting ready for final assembly.0

I’m welding up the tubes and getting ready for final assembly.0 -

One more, then cleanup with flap discs.0

One more, then cleanup with flap discs.0 -

I was finish welding the last tube today, and ran out of argon. Damn.0

I was finish welding the last tube today, and ran out of argon. Damn.0 -

Here is the modified firewall strut, tacked together and installed. I will finish weld, grind, and paint it. Maybe it won’t look quite so industrial.0

Here is the modified firewall strut, tacked together and installed. I will finish weld, grind, and paint it. Maybe it won’t look quite so industrial.0 -

I will be cutting the collector and attaching a reducer.0

I will be cutting the collector and attaching a reducer.0 -

Nice job all around. Your skills show.

That's what I envisioned for the brace.0 -

A little progress this weekend.0

A little progress this weekend.0 -

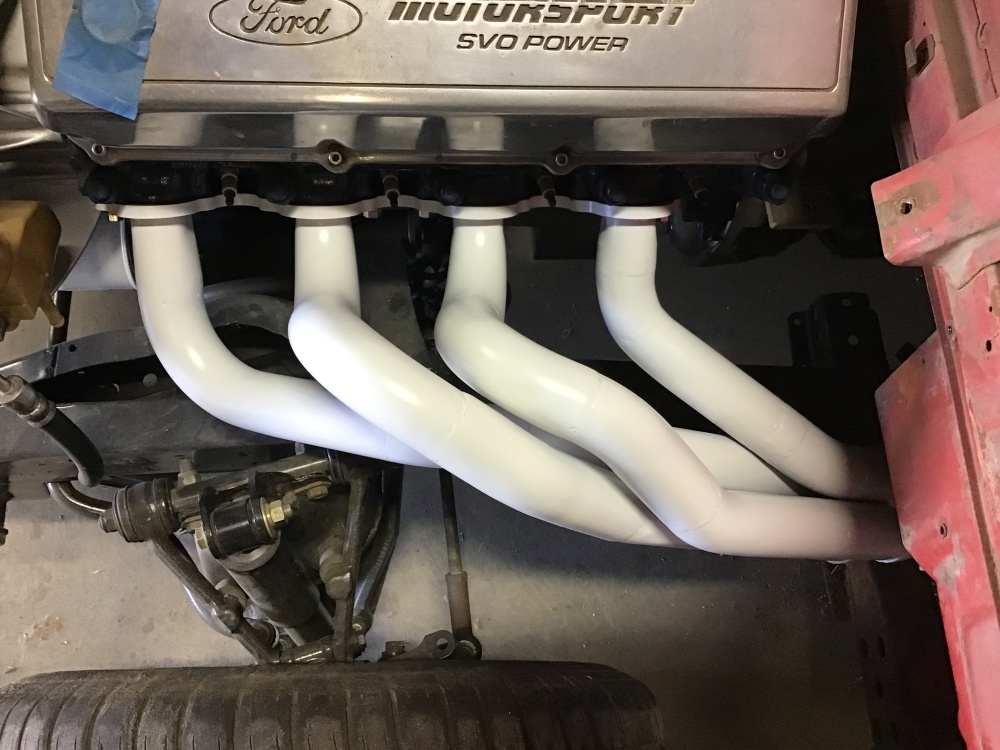

Ready for ceramic coating.0

Ready for ceramic coating.0 -

I think those are the damn finest headers I have ever seen!!0

-

Very nice.

0

0 -

I dropped the headers off to be coated on Monday. They estimated a two week turnaround.... I'm anxious.0

-

I got the call on Friday evening, that the coating was done. Four days instead of two weeks… I picked them up this morning. I really like the old school look of white headers.

I got the call on Friday evening, that the coating was done. Four days instead of two weeks… I picked them up this morning. I really like the old school look of white headers.

0 -

That's really cool. They came out nice!

0

0 -

I got to work on my car a little bit today, cutting away what was necessary to clear the headers. I still have a little more to go, and I will add material forward of the header, above the upper control arm.0

I got to work on my car a little bit today, cutting away what was necessary to clear the headers. I still have a little more to go, and I will add material forward of the header, above the upper control arm.0

Categories

- 36.9K All Categories

- 111 Hudson 1916 - 1929

- 20 Upcoming Events

- 92 Essex Super 6

- 28.6K HUDSON

- 569 "How To" - Skills, mechanical and other wise

- 995 Street Rods

- 151 American Motors

- 178 The Flathead Forum

- 49 Manuals, etc,.

- 78 Hudson 8

- 44 FORUM - Instructions and Tips on using the forum

- 2.8K CLASSIFIEDS

- 606 Vehicles

- 2.1K Parts & Pieces

- 77 Literature & Memorabilia

- Hudson 1916 - 1929 Yahoo Groups Archived Photos