Hudson eight 34 crankcase bolt

Tapez votrI recently dismantled the housing of my Hudson survivor of 34.This vehicle has never been disassembled I precise. I have removed the crankcase; cleaned and repainted. I removed the bolts which was very greasy. While cleaning; I realized that 6 of the bolts had a brass washer and the others did not. Do they have to be mounted in a well-specified place? If you could answer my question;thank youe message

0

Comments

-

The bolts that screw into the front and rear main bearing caps, and the two longer bolts on the right hand side that hold the oil intake pipe bracket have brass washers, not spring washers.0

-

Thanks for the quick response. Top of top

0 -

Probably, the oil leaks down the threads. No have not received caps.0

-

The copper washers theoretically provide a perfect seal between the head of the bolt and the oil pan, stopping any oil that leaks down the bolt threads. A spring washer can never provide a perfect seal the way a copper washer does.0

-

And personally I will put net sealing loctite

0 -

0

-

I would just point out that as far as I know, none of the perimeter oil pan bolts are directly exposed to the inside of the oil pan. If you have leaks, the pan is warped or bent, gaskets are not installed correctly, the oil drain is partially blocked by sealant or (as in my case with my 34 212), you may have a pin hole leak in the pan. As Geoff indicated, the two areas needing extra support are either side of the oil drain at the rear main and either side of the oil pickup. And at least on the 212, those bolts are not exposed to the oil gallery either. Bottom line is you don’t necessarily need any washers anywhere else on the oil pan unless you have warpage issues with your oil pan in which case a standard steel washer will help.0

-

sealing threads on the bolts concerned of course ...0

-

Sorry to disagree, but the front bearing cap bolts are directly into the interior of the crankcase. Try leaving one out and see how much oil pours out.0

-

15 to 20 ftlb0

-

I reread your post, Geoff. You’re correct on the two bearing cap bolts. However, they do not (at least on the 212’s) secure the oil pan to the block and I’m quite certain they do not on the 254 8-cylinder engines either. There’s a notch or cutout for each of the two front bearing cap bolts in the pan to accommodate them. I stand by my statement that none of the oil pan bolts are exposed to the oil chamber. I hope that clears this matter up.Toddh said:I was just inside both my ‘34 and ‘46 212’s and they are not exposed to the oil chamber, Geoff.Geoff said:Sorry to disagree, but the front bearing cap bolts are directly into the interior of the crankcase. Try leaving one out and see how much oil pours out.0 -

1 ftlb equals 1.4Nm, so 21 to 28Nm for the oil pan bolts.0

-

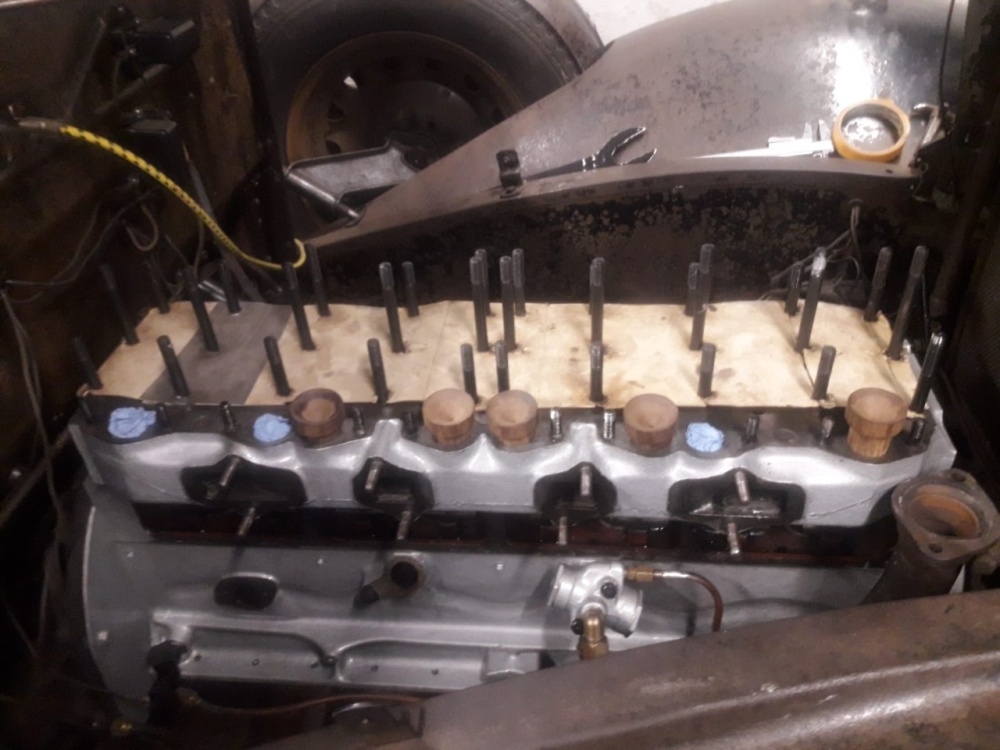

There are 4 bolts at the front and two at the rear that crosses the block and direct contact with the oil. Look in the picture; I pass a metal rod

Dale Cooper

Installation of the crankcase next week. Today it was valve adjustment

the 31 crankcase bolts. With both long for the oil sump

0 -

Ca tourne 😊

0 -

Avant

0

Categories

- 36.9K All Categories

- 111 Hudson 1916 - 1929

- 20 Upcoming Events

- 92 Essex Super 6

- 28.6K HUDSON

- 569 "How To" - Skills, mechanical and other wise

- 995 Street Rods

- 151 American Motors

- 178 The Flathead Forum

- 49 Manuals, etc,.

- 78 Hudson 8

- 44 FORUM - Instructions and Tips on using the forum

- 2.8K CLASSIFIEDS

- 606 Vehicles

- 2.1K Parts & Pieces

- 77 Literature & Memorabilia

- Hudson 1916 - 1929 Yahoo Groups Archived Photos