Fun with pistons and rings

I finally got around to pulling the head, then the pan, then the #3 piston out of the 1954 308 in my 51 Hornet. It had been running ok, but using about a quart of oil every hundred miles, which is a bit too much for my tastes.

A few pictures....

0

Comments

-

Boy, that #2 ring land looks beat up. #2 piston hole sucking oil?

0 -

there is no obvious cylinder sucking oil....oil is all present in all the holes, and none of the plugs are oil fouled after driving 1200 miles or so.I have to pull more pistons out and do some careful measuring....0

-

Thanks for sharing Squirrel! I’ll be interested to know what you find as you dig deeper. Any idea what re-freshening direction you may look to go with the engine?0

-

Years ago, we had a 49 that lost one of it's piston ring pins like that. It bounced around until at one point, when the piston came up, it was standing on top of the piston. It cracked the head, and punched a hole in top of the piston.0

-

My guess is worn valve guides and/or valve stems.0

-

I did some more measuring, it appears the #3 piston is actually .030" over, the rest are .020" over. Very interesting. I did a preliminary hone on #3 and #4, and revealed a nice 1/8" wide by .001-.002" deep groove in #3. #4 has less than .005" taper. #3 has a lot more than that....closer to .015", which is a bit much. #3 has noticeable slop in the piston pin to piston fit, as well.I should pull the engine out, punch them all out to .060, and buy new pistons, and replace the bearings (and get the crank turned), get the cam ground, lifters refaced, valve job, new valve springs, new timing set, etc. But I would like to spend only a few hundred bucks, so it would be cool to get a set of original type .020" over rings, and one .030" piston and ring set. But I dont know how far off the replacement 3 ring type piston weights are, if I would have a vibration issue.Being in cheapskate mode really makes an engine repair job into a fun challenge.0

-

WOW! I would have never guessed that situation in your engine. I wonder if the pistons were somehow balanced in weight?

This web site by Ken Cates has a bunch of great information on the big 6 cylinder engine, it might help.

https://hudsonrestoration1948-54.com/Engine.htm

0 -

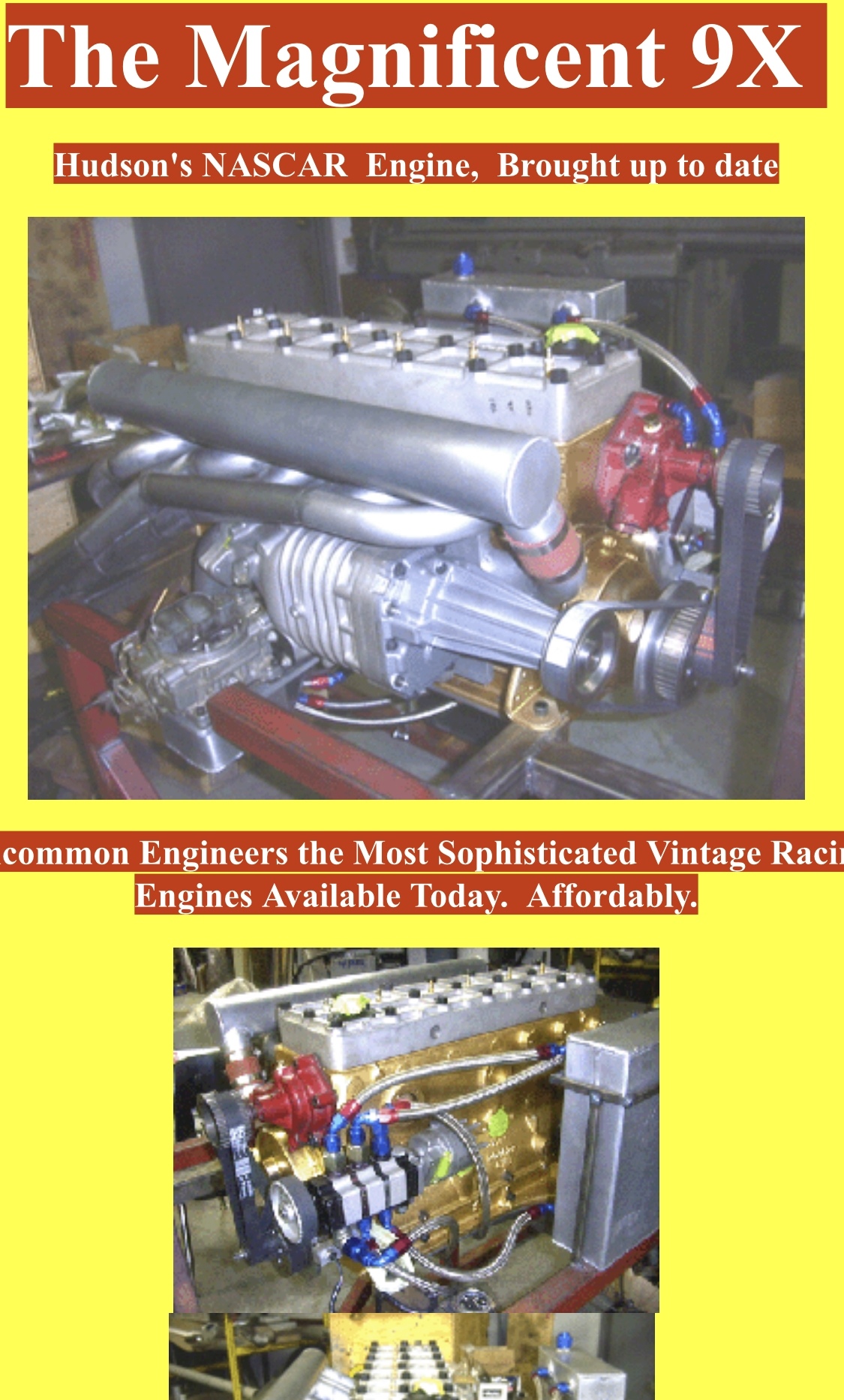

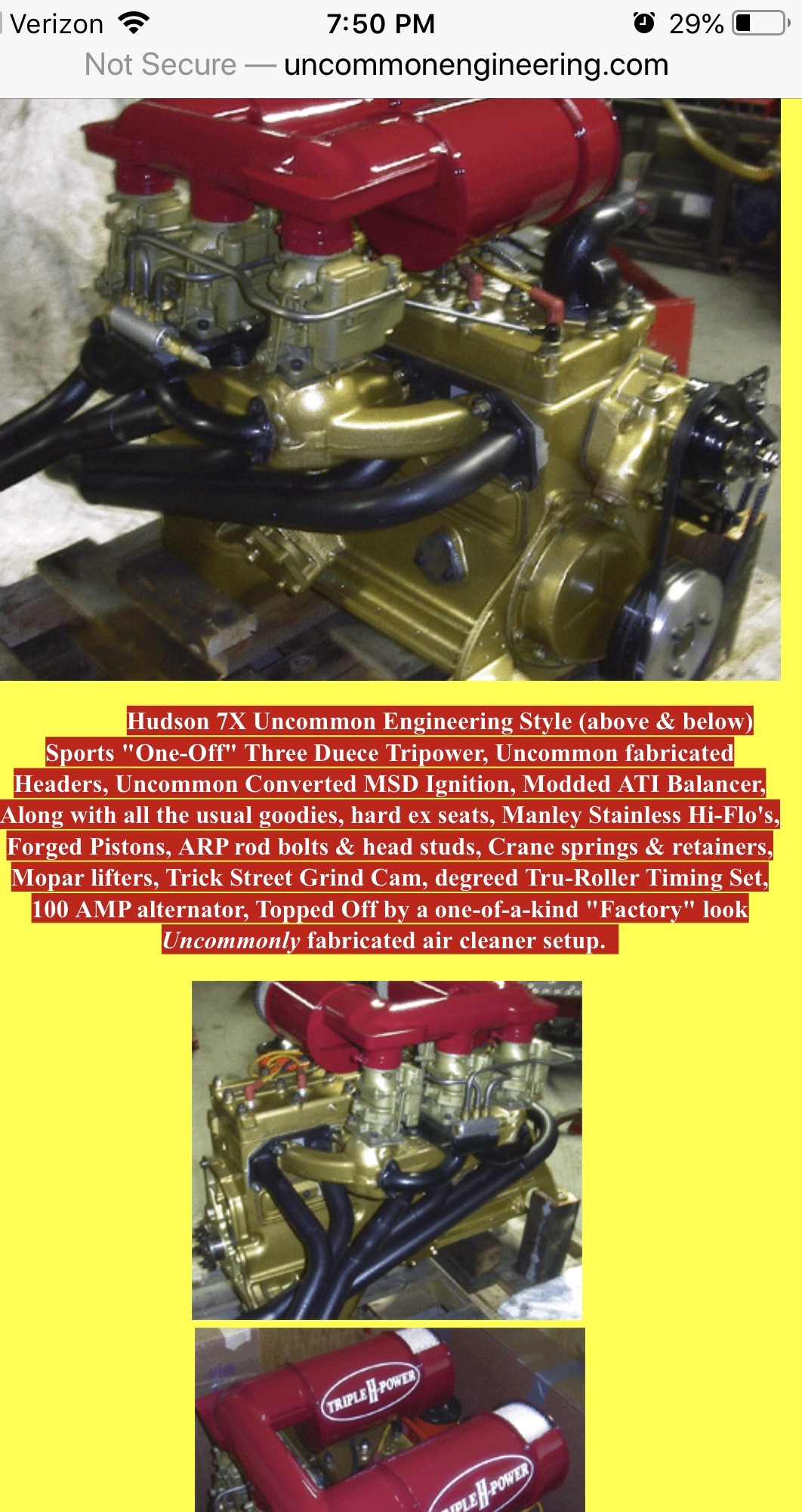

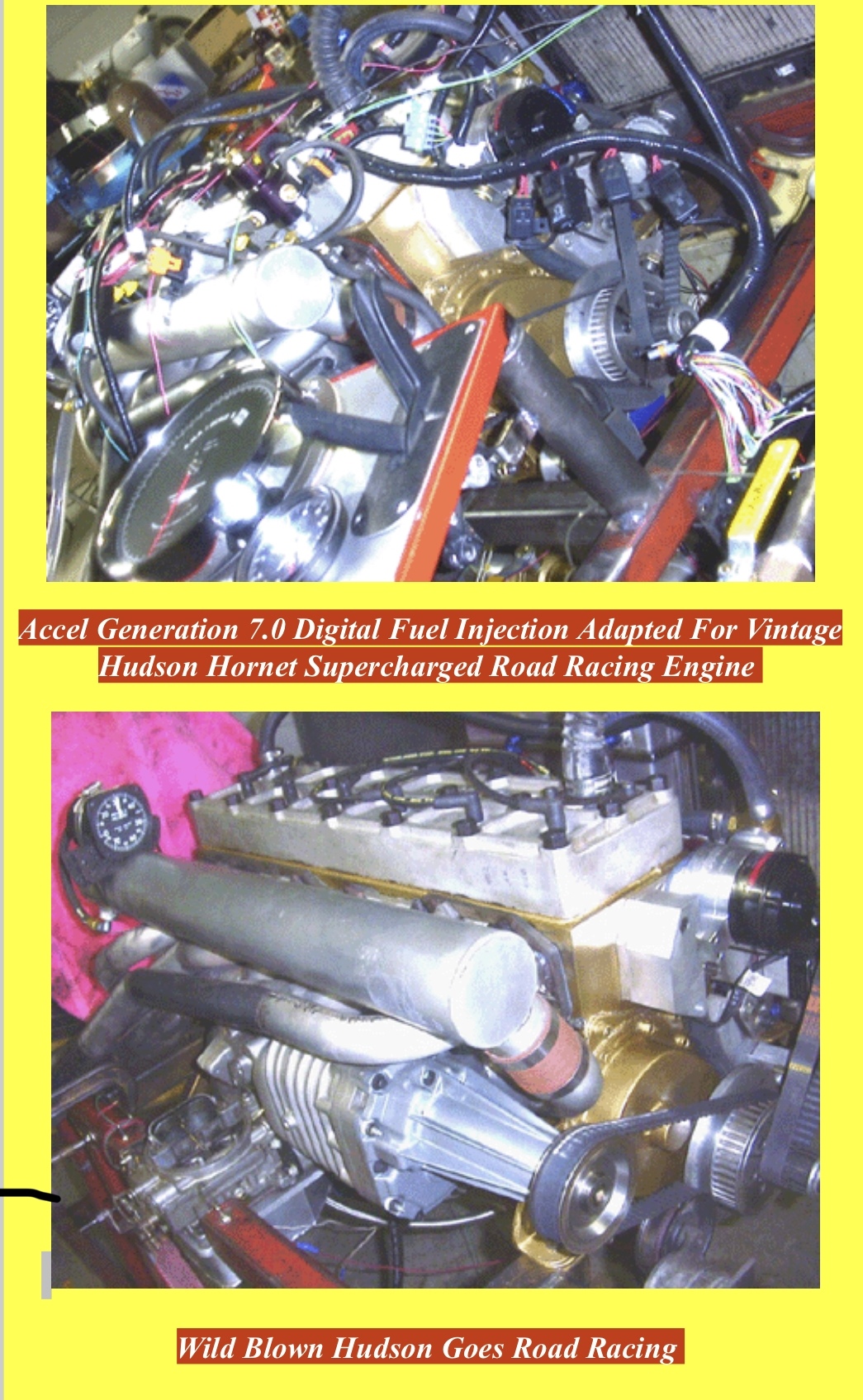

Just in case you haven’t seen this website, something to get ya thinking about that rebuild!

0 -

those don't look like $200 rebuilds, to me.

I talked to Dale today, he's going to see if he has the parts I need0

I talked to Dale today, he's going to see if he has the parts I need0 -

Here’s a really great resource I ran across the other day, good information there!

https://www.jalopyjournal.com/forum/threads/hudson-232-262-308-engine-tech.539734/

0 -

Uncommon engineerings siteWonder if anyone here has worked with them?

0 -

That looks like a fun and challenging rebuild.

0 -

Yeah, it's keeping me on my toes.0

-

I got the hone today, and after fixing a minor defect that made it unusable, I honed #3 cylinder. I got the bottom to be .040" over, the top to be about .042 over, and the middle is about .045 over. There are two areas of ring wear that did not hone out, as well as that pesky scratch. It should last for 10k miles or more, though....based on my years of experience doing hack engine repair jobs every now and then.

0

0 -

Well , it's got to be better than it was. It will burn some oil , but hopefully not foul the plug. good luck.0

-

Looking good so far, keep it up!

0 -

That's the goal.,thanks!0

-

Got my new old stock Cadillac rings in the mail today, and ground the ends down 1/32" so they'd fit the .020" bores. Going back together.

0

0 -

It's back together and running. We'll see tomorrow how much it smokes.

0

0 -

That wasn't so hard. lol

Good work , and good luck

0

Categories

- 36.9K All Categories

- 111 Hudson 1916 - 1929

- 20 Upcoming Events

- 92 Essex Super 6

- 28.6K HUDSON

- 569 "How To" - Skills, mechanical and other wise

- 995 Street Rods

- 151 American Motors

- 178 The Flathead Forum

- 49 Manuals, etc,.

- 78 Hudson 8

- 44 FORUM - Instructions and Tips on using the forum

- 2.8K CLASSIFIEDS

- 606 Vehicles

- 2.1K Parts & Pieces

- 77 Literature & Memorabilia

- Hudson 1916 - 1929 Yahoo Groups Archived Photos