Removing 46 Oil Check Valve

longlivelance

Member

I am trying to remove and oil check valve so that I can verify it is opening. Looking at the 42-47 mechanical procedure manual, it looks like the entire unit should unscrew from the block. In the manual it mentions a J-1454 tool that is used to remove it. I've tried to unscrew it and it wont budge.

Are there any tricks, or an alternative tool I can use to get that thing off without breaking something?

Are there any tricks, or an alternative tool I can use to get that thing off without breaking something?

0

Comments

-

You will have to remove the bottom fitting to give enough room to turn it around as you unscrew it, otherwise the elbow will li9mit against the engine plate. Just use a large adjustable wrench on the body of the valve and unscrew it anti-clockwise0

-

You are right, its held into the block on a tapered pipe thread. I remember mine was hard to get to move, I think I moved something else out of the way and then I was able to get a pipe wrench or big open end spanner on to the upper part.0

-

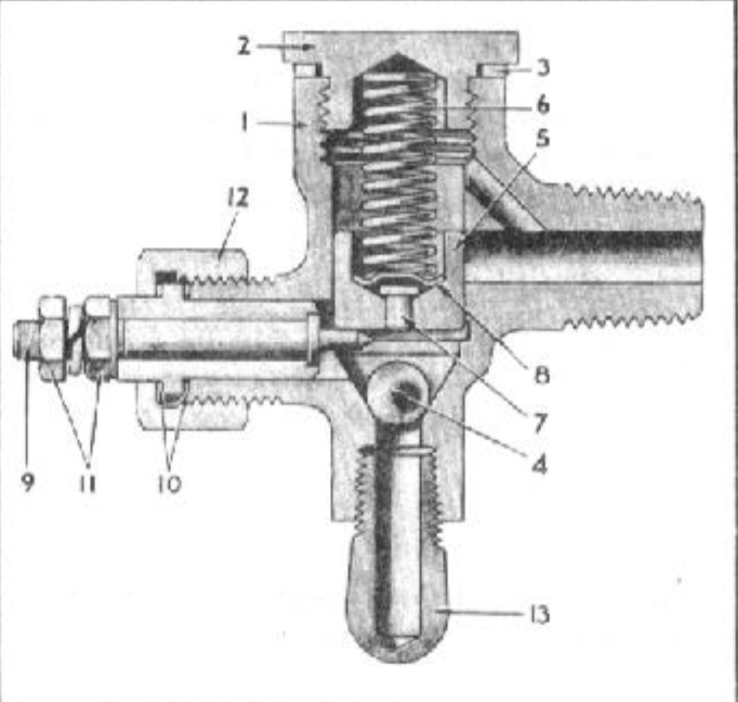

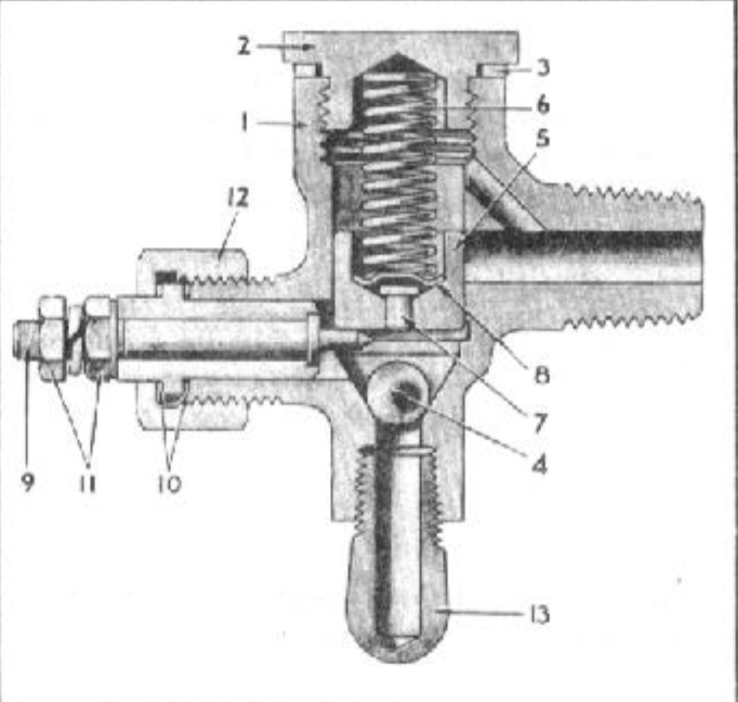

Thanks all, got it off this morning. Never taken one of these apart, but from the diagram it looks like everything is there.

I had a couple of questions about it to be sure it is ok before I put it back together.- I was wondering if the pin (#7) in that sprint retainer cup, is supposed to move? I see what looks to be it, but it does not move at all, so not sure. Is that normal?

- Should the pressure from the oil just push the valve ball (#4) up, and in turn lift the cup (#5) allowing the oil to pass into the block?

- Is there a way to bench test the light terminal (#9) to make sure it is all working before putting it back in?

0 - I was wondering if the pin (#7) in that sprint retainer cup, is supposed to move? I see what looks to be it, but it does not move at all, so not sure. Is that normal?

-

Assemble it and check that you have continuity with an ohm meter. don't try and take the pin out, or the insulating post.0

-

Thanks Geoff! Just tested it on the bench and saw continuity. Put it back on the truck and put the ignition on. Saw continuity, then started the engine. Continuity stopped. Turned the engine off, and in around 5 minutes, continuity returned.

Feel a lot better knowing the engine is 100% getting lubrication now.0 -

That sound normal. The reason for the long period before the light comes on again is the ball check that keeps the pressure up in the sender unit. if the ball was not there the light would flash on and off when idling.0

-

Good to know. I was happy to take it apart and see how simple it was, and exactly how it works. Thanks everyone for the guidance! Glad to have gotten this taken care of.

Now onto the next adventure....brakes.0

Categories

- 36.6K All Categories

- 85 Hudson 1916 - 1929

- 11 Upcoming Events

- 73 Essex Super 6

- 28.3K HUDSON

- 511 "How To" - Skills, mechanical and other wise

- 989 Street Rods

- 150 American Motors

- 170 The Flathead Forum

- 47 Manuals, etc,.

- 71 Hudson 8

- 40 FORUM - Instructions and Tips on using the forum

- 2.7K CLASSIFIEDS

- 592 Vehicles

- 2.1K Parts & Pieces

- 76 Literature & Memorabilia

- Hudson 1916 - 1929 Yahoo Groups Archived Photos