How to Re-Install Oil Pan After Cleaning

I’m ready to re-install the oil pan on my 37’s 212ci engine however I’m trying to determine if there is a use for the o-ring that came with the two pan gaskets. If it is to be used, where exactly does it go?

I’m ready to re-install the oil pan on my 37’s 212ci engine however I’m trying to determine if there is a use for the o-ring that came with the two pan gaskets. If it is to be used, where exactly does it go?The o-ring is too large to fit into the hole in the side of the block where the pickup tube goes into the block. If placed directly below the block & on top of the upper gasket, I imagine it could allow oil to leak around it since I t doesn’t look like the pan gasket is thick enough to take up the space.

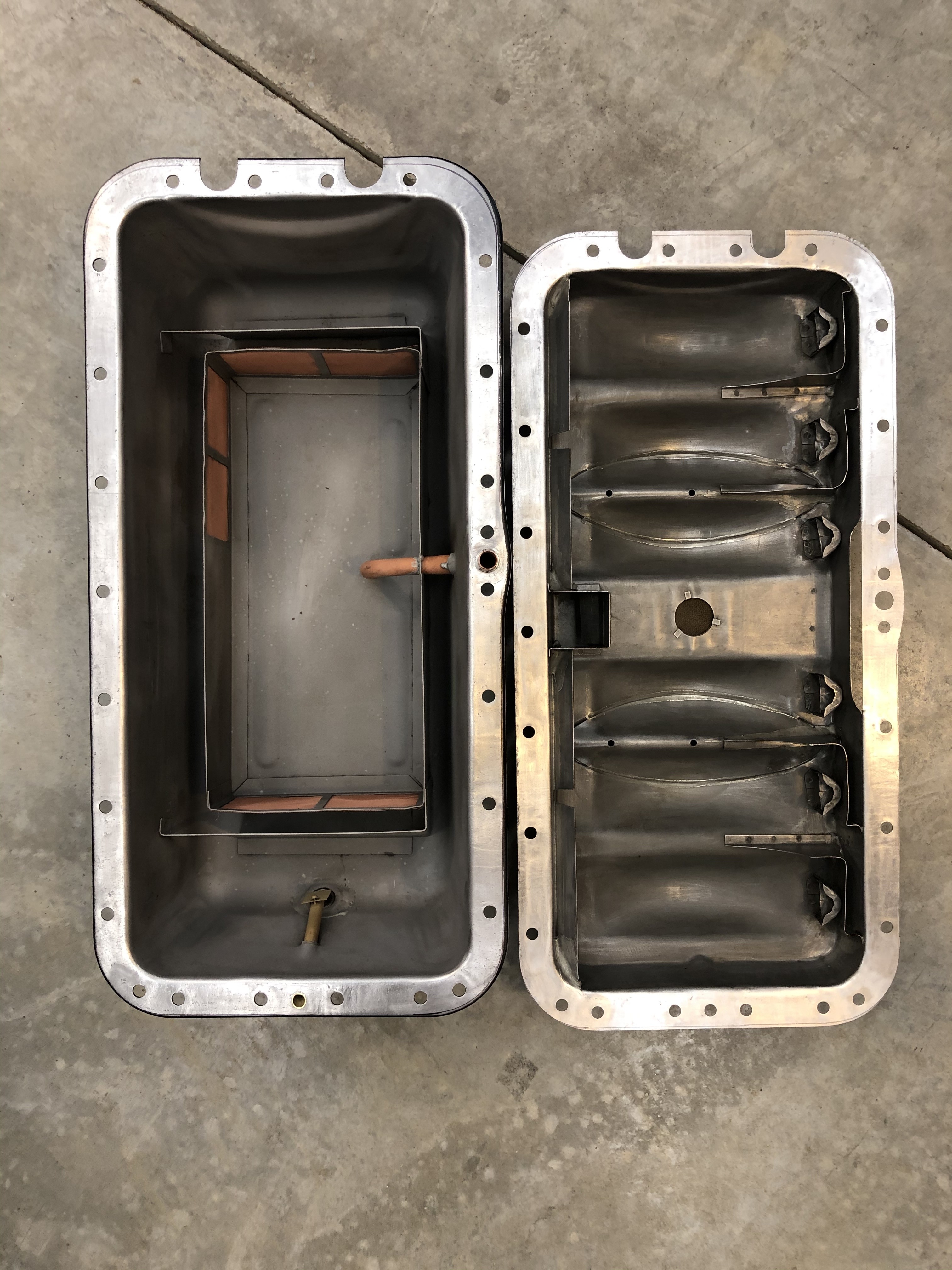

All surfaces of the pan & trough have been cleaned & prepared as well as the block surface.

Finally is the a specific bolt tightening pattern to follow? How about torque specs?

Finally is the a specific bolt tightening pattern to follow? How about torque specs?

0

Comments

-

I used copper coat on the surfaces then sewing thread to tie each bolt hole of the gaskets together - somewhat tedious but secure - left thread in place as I put in bolts (with upper tray filled with motor oil. Harder to do on the straight eight ! Gert Kristiansen0

-

Not sure if this is the same o ring, but this was on my splashier pan for my 46 when I just dropped it.

0

0 -

I got gaskets from Dale Cooper and used a little ultra copper set the pan assembly on a transmission jack, fill top pan with one quart and slowly lift into place.0

-

I finally found some information on the oil pan gasket & the o-ring. What I discovered was prior to 1939 there was no o-ring used. Since the Best Gasket oil pan gasket goes up through 1947 the o-ring is included. Thus, for my 1937, no o-ring needed.0

-

If you use long bolts on the sump corners say 6" there is room to assemble and hang the sump on the long bolts and fill with oil. Then push sump up and insert the proper shorter bolts. Or fill up oil through a tappet cover.0

-

Good idea on holding up the pan with longer bolts to give access to fill the upper tray. However, I want to make sure I keep my gasket free of oil, so I am planning to pour the oil through the valve/tappet area & let it drain down into the trough. It should also work it’s way to some other key areas like the front & rear mains. Even though I poured some oil into all the main’s feeder holes before I installed the pistons, it sure can’t hurt anything to add some more.I worry about the pump sucking air in as it pumps so I’d still like to find an o-ring that I could use around the pick up tube that fits into the block. I tried the o-rings I had Last night & they were all too thick.0

-

Test fitting the oil pan trough I found why I had a deformity at the edge of one hole in the trough. When aligned up it was discovered the stamped hole was off a little & when the bolt was installed it was forced over & bent the trough hole. After a little Dremel work it won’t be a point for a future leak.

0

0 -

Something I have done in the past, is assemble the two pans, and the two gaskets, and tie them all together with sewing thread through the bolt holes, in four or five places down each side of the pan. you can then install it all as a unit. put in all of the bolts loosely, and cut the ties and remove the threads before tightening the bolts. It works for me.0

-

That’s a good idea, something to keep it all together is Definitely helpful. I ended up putting some of the bolts in the holes (6-8) then when raised up I could start to screw some in. I did not use any O-Rings since they just wouldn’t work correctly.From there I used a phillips screwdriver in the hole to get the gasket lined up if needed, keeping them all loose enough to move things around if needed. Not finding any specific bolt tightening pattern I just went to each side of the pan, back & forth tightening the bolts a little at a time around the pan. I believe the torque valves are around 15ft/lbs however I just went to a good firm hand tightening for now, I’ll need to pick up a smaller torque wrench as all of mine are too large. Finally, I replaced all the bolts & washers with stainless steel.

0

0

Categories

- 36.6K All Categories

- 85 Hudson 1916 - 1929

- 11 Upcoming Events

- 73 Essex Super 6

- 28.3K HUDSON

- 511 "How To" - Skills, mechanical and other wise

- 989 Street Rods

- 150 American Motors

- 170 The Flathead Forum

- 47 Manuals, etc,.

- 71 Hudson 8

- 40 FORUM - Instructions and Tips on using the forum

- 2.7K CLASSIFIEDS

- 592 Vehicles

- 2.1K Parts & Pieces

- 76 Literature & Memorabilia

- Hudson 1916 - 1929 Yahoo Groups Archived Photos