Leaking Water Jacket Cover on 1934 Hudson

Old Fogey UK

Expert Adviser

in HUDSON

I posted about my water jacket a little while ago.

I managed to patch up the rust holes in the cover with JB Weld and am waiting for the ROC to get a new batch of stainless steel covers made up.

I re-installed it using a home-made cork gasket sealed with with a smear of silicone and that has proved completely watertight.

I used new stainless steel screws to attach it, smearing the threads with Wellseal, but I've got a number of slight water leaks around some of the screw heads.

These disappear when the engine is running - due to heat expansion I suppose - but reappear after everything cools down.

Has anyone experienced the same problem with water jacket screws ?

I might try but some extra Wellseal on the threads but would wrapping the threads in PTFE tape or smearing them with silicone sealer be a better solution ?

I'd appreciate people's thoughts, please, before attempting a remedy.

I managed to patch up the rust holes in the cover with JB Weld and am waiting for the ROC to get a new batch of stainless steel covers made up.

I re-installed it using a home-made cork gasket sealed with with a smear of silicone and that has proved completely watertight.

I used new stainless steel screws to attach it, smearing the threads with Wellseal, but I've got a number of slight water leaks around some of the screw heads.

These disappear when the engine is running - due to heat expansion I suppose - but reappear after everything cools down.

Has anyone experienced the same problem with water jacket screws ?

I might try but some extra Wellseal on the threads but would wrapping the threads in PTFE tape or smearing them with silicone sealer be a better solution ?

I'd appreciate people's thoughts, please, before attempting a remedy.

0

Comments

-

Sorry if I've confused anyone - I meant to say stainless steel set screws/bolts.0

-

I have to reassemble mine soon. I think the joint is a paper joint. I will put mesh sealing on the screws. Do you have the brass washers with your bolts?

RIGHT BOLL

0 -

They used to have small copper washers for that.0

-

On my 1934 survivor never disassembled; these are brass washers

0 -

I’ve seen small round like donuts washers that were compressible when tightened.0

-

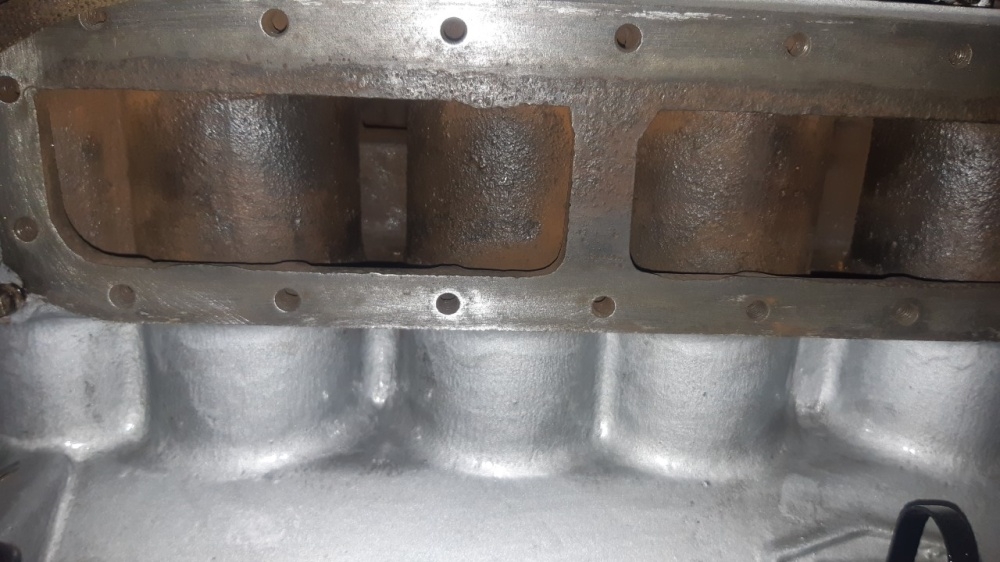

My water jacket restores

0 -

That’s the first thing that needs to be done on one that’s been off the road for years unless it looks like it’s already been done. Takes a while to clean out around the rear cylinders where the crud seeks to collect.0

-

a tiny part of the grime scraped around the cylinders

0 -

Jack356 , those are the cleanest cylinder walls I’ve ever seen. You say your motor is a survivor and never been rebuilt? Wow0

-

Not ever rebuilt. I just do some cleaning. But hey; hours to scratch around the cylinders with mini brushes;hooks .....

0 -

The wire of my car here ;p not pollute our friend's post.

I wish I could change the title of the post.

https://forum-hetclub-org.translate.goog/discussion/365896/intake-valve-hudson-8-1934?_x_tr_sl=en&_x_tr_tl=fr&_x_tr_hl=fr

0 -

CRC Grey gasket is the best to use around the threads and studs. As stated , brass washers were used, and the grey gasket compound in conjunction with these will do the job0

-

I’ll second Geoff’s comment. I put thread sealer on the bolts rather than the gasket sealant. I didn’t want to chance a ball of hard gasket sealant floating around my radiator system. Used brass washers. Make sure you don’t over torque the bolts.0

-

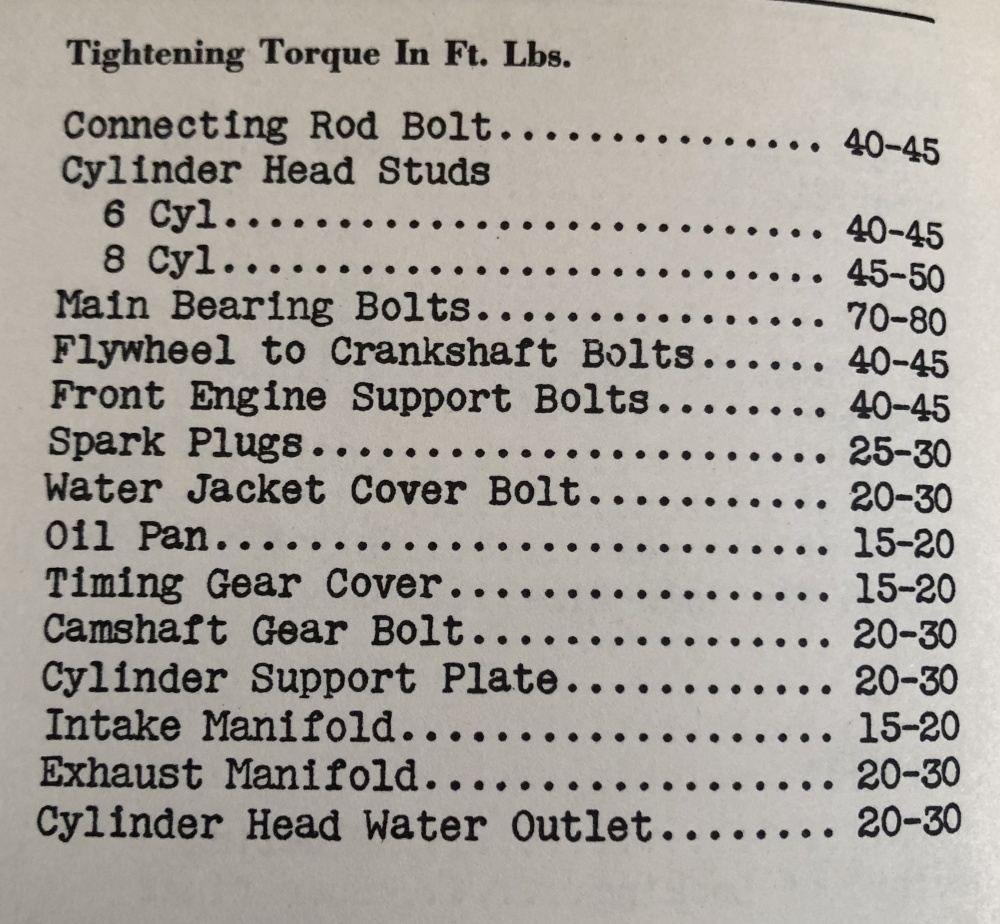

A tightening torque can be?

0 -

From the 42-47 Mechanical Procedure manual.

From the 42-47 Mechanical Procedure manual.

0 -

Merci.Ca must not be very different for an 8-cylinder from 1934?

0 -

It’s essentially the same engine used through 19520

-

Thank you everyone.

I'll try to get some CRC as Geoff suggests.

I've used red fibre washers underneath steel washers with the bolts (that's what were there when I got the car and it ties in with the ROC procedure manual).

Should I substitute soft copper washers ?0 -

Problem with fibre washers is that you cannot torque them tight enough without them crumbling, and eventually failing in service. Copper or brass would be better.0

-

Can be put all the new brass washers. My survivor 34 never disassembled only had brass washers under the bolt

0 -

Thanks Geoff.

Copper washers it is !

Thanks to Toddh for the torque settings; I've been afraid to tighten the bolts to much because of the fibre washers breaking up.

Should I still put steel washers on top of the copper ones ?0 -

BRASS ONLY ........

0 -

BRASS ONLY

0 -

Fogey - Chase out the block threads with a tap. Make sure they’re clean and crisp. I used new stainless bolts and copper washers. I also used thread sealant rather than gasket goop for the reasons I mentioned above0

-

As in many past engines, I shorten the new mounting bolts so they do not enter the coolant cavity. The Grey CRC is used.

I put two nuts on the bolt, grind the exposed threads off and removeing the nuts cleans up the threads for easy installation. This closely approximates the thickness of the block at threaded area.

Right now I am repairing the water jacket mounting holes in another Essex block, 1929. The origional bolts protude into coolant and rust. Of the 16 bolts 8 broke off. No amount of penetrating solutions will soak in to reduce the swelling of the threads in the coolant cavity.

Note. Bolt retention is not determined buy the amount of thread protruding into the coolant. Rule is, the effective penitration length of the bolt is equal to diameter of bolt threads.0 -

I am lucky on my survivor 1934.J have well heated with the heat stripper and have not broken any stud. Although never dismantled. I will go up as it is;with the original bolts;sealing loctite net and brass washer.

0 -

Thanks Todd and Jackie.

I'll just use copper washers (I think brass washers won't squash down as much copper washers) and I'll try Loctite Blue on the bolt threads rather than Wellseal.

Loctite Blue has provided a totally leak-proof seal on my water temperature sensor fitting's threads and should do the same on the water jacket.0 -

Wow! the Griffins are smiling on me - this is a very timely post as I hope to replace the water jacket on my 33 non terraplane this weekend. Thanks for all the tips!0

-

Let us know how successful you are - my local hardware store is out of the correct size copper washers, so my job is on hold for a few days until they re-stock them.0

-

Sur amazone

Order today received tomorrow

0

Categories

- 36.6K All Categories

- 85 Hudson 1916 - 1929

- 11 Upcoming Events

- 73 Essex Super 6

- 28.4K HUDSON

- 511 "How To" - Skills, mechanical and other wise

- 990 Street Rods

- 150 American Motors

- 170 The Flathead Forum

- 47 Manuals, etc,.

- 71 Hudson 8

- 40 FORUM - Instructions and Tips on using the forum

- 2.7K CLASSIFIEDS

- 592 Vehicles

- 2.1K Parts & Pieces

- 76 Literature & Memorabilia

- Hudson 1916 - 1929 Yahoo Groups Archived Photos