Rebuilding Rear Leaf Springs - 46 Hudson Pickup

46HudsonPU

Administrator

Am considering replacing the differential of my '46 Hudson pickup ('stump puller', with 4.59 gears).

- As part of that (i.e., as long as I am there), I am looking at other items (leaf springs, mountings, emergency brake cable, etc..). Did a search of the threads, found very little on this, nothing pertaining to rebuilding/repairing the leaf springs (?).

Many (those with these Hudson pickups) are very aware of the stiffness, etc., of these leaf springs. As long as I am focused on pulling out these springs to rebuild them, I might as well consider making the ride a bit more 'friendly'.

Has anyone re-built these rear leaf springs, hopefully on a pickup, however maybe even a LWB sedan? My primary thoughts are -

- Reducing the number of leafs, probably by about 1/3;

- Rebuilding/replacing the shackles, center pin(s), leaf retention hardware, etc., as I go through it;

- Checking (for cracks, etc), each leaf, stripping and re-painting;

Am in the primary stages of this - original differential has been removed, and am having 'fun' in my attempts to remove the leaf springs..

Thoughts, concerning any/all of the above, and recommendation(s), links for parts, pieces, etc., for the leaf springs?

As always, any recommendations, assistance (with links for parts, etc.,), are appreciated!

- As part of that (i.e., as long as I am there), I am looking at other items (leaf springs, mountings, emergency brake cable, etc..). Did a search of the threads, found very little on this, nothing pertaining to rebuilding/repairing the leaf springs (?).

Many (those with these Hudson pickups) are very aware of the stiffness, etc., of these leaf springs. As long as I am focused on pulling out these springs to rebuild them, I might as well consider making the ride a bit more 'friendly'.

Has anyone re-built these rear leaf springs, hopefully on a pickup, however maybe even a LWB sedan? My primary thoughts are -

- Reducing the number of leafs, probably by about 1/3;

- Rebuilding/replacing the shackles, center pin(s), leaf retention hardware, etc., as I go through it;

- Checking (for cracks, etc), each leaf, stripping and re-painting;

Am in the primary stages of this - original differential has been removed, and am having 'fun' in my attempts to remove the leaf springs..

Thoughts, concerning any/all of the above, and recommendation(s), links for parts, pieces, etc., for the leaf springs?

As always, any recommendations, assistance (with links for parts, etc.,), are appreciated!

0

Comments

-

You can always buy new springs. They can make them any stiffness you want. A little pricey but will be perfect.

0 -

Thank you for both the suggestion, and the link. I am considering that, as well. Maybe if things don't 'work out', or if I have issues..ski4life65 said:You can always buy new springs. They can make them any stiffness you want. A little pricey but will be perfect.0 -

A couple of hours in the workshop, and the rear springs are 'on the bench'. My count is 12 leaves to each spring. The plan here is to count '1-2-3' (top to bottom), and begin again. Every 3rd leaf will be removed. Thoughts?

The right-rear shackle was not exactly 'standard', took a bit of persuasion (and a cut-off disk on my angle grinder) to get that loose. You'll note that the shackle bolts were welded - no attempt to loosen - went straight to the cutting wheel..

Wasn't holding together too well anyway..

I should point out that this set of leaf springs didn't come from the same Hudson pickup that will eventually get the rebuilt/refurbished leaf springs and rebuilt differential. The '46 Hudson pickup that these leaf springs came from is 'another, different project'. It was sold to me as a 'runner' when I bought it - it wasn't, and continued to frustrate and disappoint, as I looked further and further into it. However, that's a 'story' for another post - when the time comes for that 'build'..

0 -

Well, one is disassembled - Had to cut most of the bolts/nuts. If you're doing this, USE CLAMPS, as the leaves have 'static energy', and you don't want to get struck by flying metal. I put clamps on each side, before any cutting, then eased off on the tension..

I am in need of shackles, bushings, etc., to hang these leaf springs on my '46 Hudson pickup. Prefer NOS - either Hudson or aftermarket..

Leaf Spring Bolts and bushings (forward position, rear leaf springs) - 4 8 each (2 bushings required for each leaf spring)

Leaf Spring Shackles and bushings (rear position, rear leaf springs) - 2 4 each (two left/two right, as applicable)

0 -

I've been looking at leaf springs in the aftermarket, and what they offer only have 3-4 leaves (?). I realize that improvements in composition of metals have contributed significantly, lessening the need for so many leaves, while still providing adequate support.DocHubler said:I removed about 1/2 the springs from my 41 1/2T pickup. The originals are essentially overload springs that make the truck ride like a buckboard wagon

Honestly, I think that Hudson over-did it, at least on the trucks/commercial series rear suspension.

Questions:

- What did you do about the 'rebound clips' (those side straps, holding the spring leaves in place)? As I noted (seen in my photos), they are riveted to certain leaves..

- Did you put shocks on your pickup to help with the ride? If so, what manufacturer, part no., etc.?0 -

Eaton Detroit Spring has lots of information about leaf springs. Especially do's and don'ts that are pretty important.

And yes, the metals used today are quite a bit different and more can be done with less.

I have researched a bit as well for my 36. Eaton is $pendy but they can make just about anything you want.

I think I did get some pieces for my silent shackles from Rare Parts. Not cheap but good quality.

Good luck,

Jeff0 -

Hudson folks - I am in need of shackles, bushings, etc., to hang these leaf springs on my '46 Hudson pickup. Prefer NOS - either Hudson or aftermarket.. Leaf Spring Bolts and bushings (forward position, rear leaf springs) - 2 each Leaf Spring Shackles and bushings (rear position, rear leaf springs) - 2 each (one left/one right, as applicable) If you can help with these parts, please message me on this forum, or email me - XXX46HudsonPU@gmail.com (remove the three 'XXX' from the email address) Have put 'feelers out' (looking for parts) to several businesses & HET Club members, no response thus far. Am anticipating that I WILL have issues (goes with the age of these vehicles), and will most likely need at least two sets, one set for each of my trucks..

I am in need of shackles, bushings, etc., to hang these leaf springs on my '46 Hudson pickup. Prefer NOS - either Hudson or aftermarket..

Leaf Spring Bolts and bushings (forward position, rear leaf springs) - 2 4 each

Leaf Spring Shackles and bushings (rear position, rear leaf springs) - 2 4 each (two left/two right, as applicable)

0 -

jjbubaboy said:Eaton Detroit Spring has lots of information about leaf springs. Especially do's and don'ts that are pretty important.

And yes, the metals used today are quite a bit different and more can be done with less.

I have researched a bit as well for my 36. Eaton is $pendy but they can make just about anything you want.

I think I did get some pieces for my silent shackles from Rare Parts. Not cheap but good quality.

Good luck,

Jeffski4life65 said:You can always buy new springs. They can make them any stiffness you want. A little pricey but will be perfect.

Well - I got word back from 'Mike' @ Eaton Detroit Spring. He indicates they don't have ANY of the attaching hardware for my '46 Hudson pickup (?), AND - doesn't know of anyone who can help me (?!?)..

I don't know about you, but I AIN'T about to buy leaf springs from them if they can't provide the other (necessary) hardware to put them on the truck..

Looks like we might have to begin getting 'creative', and find other 'solutions -

- Anybody have any legitimate, real world ideas?;

- Or maybe sitting on a 'boatload' of Hudson parts?0 -

46HudsonPU said:jjbubaboy said:Eaton Detroit Spring has lots of information about leaf springs. Especially do's and don'ts that are pretty important.

And yes, the metals used today are quite a bit different and more can be done with less.

I have researched a bit as well for my 36. Eaton is $pendy but they can make just about anything you want.

I think I did get some pieces for my silent shackles from Rare Parts. Not cheap but good quality.

Good luck,

Jeffski4life65 said:You can always buy new springs. They can make them any stiffness you want. A little pricey but will be perfect.

Well - I got word back from 'Mike' @ Eaton Detroit Spring. He indicates they don't have ANY of the attaching hardware for my '46 Hudson pickup (?), AND - doesn't know of anyone who can help me (?!?)..

Looks like we might have to begin getting 'creative', and find other 'solutions' -

- Anybody have any legitimate, real world ideas?;

- Or maybe sitting on a 'boatload' of Hudson parts?

This company has obsolete and rare parts... could be a source? They suggest calling to discuss your requirements

Rebuilders Choice provider of Obsolete American Engine, Brake and Suspension auto parts. website: https://rebuilderschoice.com Phone: 1-800-768-3646

0 -

Thank you - I'll give them a call. I'll post the results, if any..Glowplug said:This company has obsolete and rare parts... could be a source? They suggest calling to discuss your requirements

Rebuilders Choice provider of Obsolete American Engine, Brake and Suspension auto parts. website: https://rebuilderschoice.com Phone: 1-800-768-36460 -

Modern steels undoubtedly have tighter control over their composition than steels of 70 years ago but counter intuitively that only has a marginal effect on their strength or springiness or resistance to bending.

If you were to do a comparison test between identical old and new spring leaves - same thickness width and length - they would both bend the same amount for the same load.

The reason modern leaf springs can get away with using less material than older springs is purely a design and economics consideration, one 1/2" thick leaf has the same resistance to bending - again counter intuitively - as a stack of eight 1/4" leaves or a stack of four 5/16" leaves.

If you can alter your existing ute springs to mimic those of a 46 sedan you should have a sedan ride.0 -

Have been going back and forth with emails to 'Mike' at Eaton Detroit Springs -46HudsonPU said:Well - I got word back from 'Mike' @ Eaton Detroit Spring. He indicates they don't have ANY of the attaching hardware for my '46 Hudson pickup (?), AND - doesn't know of anyone who can help me (?!?)..

I don't know about you, but I AIN'T about to buy leaf springs from them if they can't provide the other (necessary) hardware to put them on the truck..

Looks like we might have to begin getting 'creative', and find other 'solutions -

- Anybody have any legitimate, real world ideas?;

- Or maybe sitting on a 'boatload' of Hudson parts?

- They no longer have any of the Hudson Shackles, however they do carry a universal, generic shackle that will work in it's place - and on the positive side, it is not specific to the side of the vehicle (I'm told that they will work on either left or right side).;

- They do not have the large, round-headed bolt to connect the front of the rear leaf springs, but do carry the bushings. I think I can clean up and re-use the old bolts (will need new nuts and locking washers);

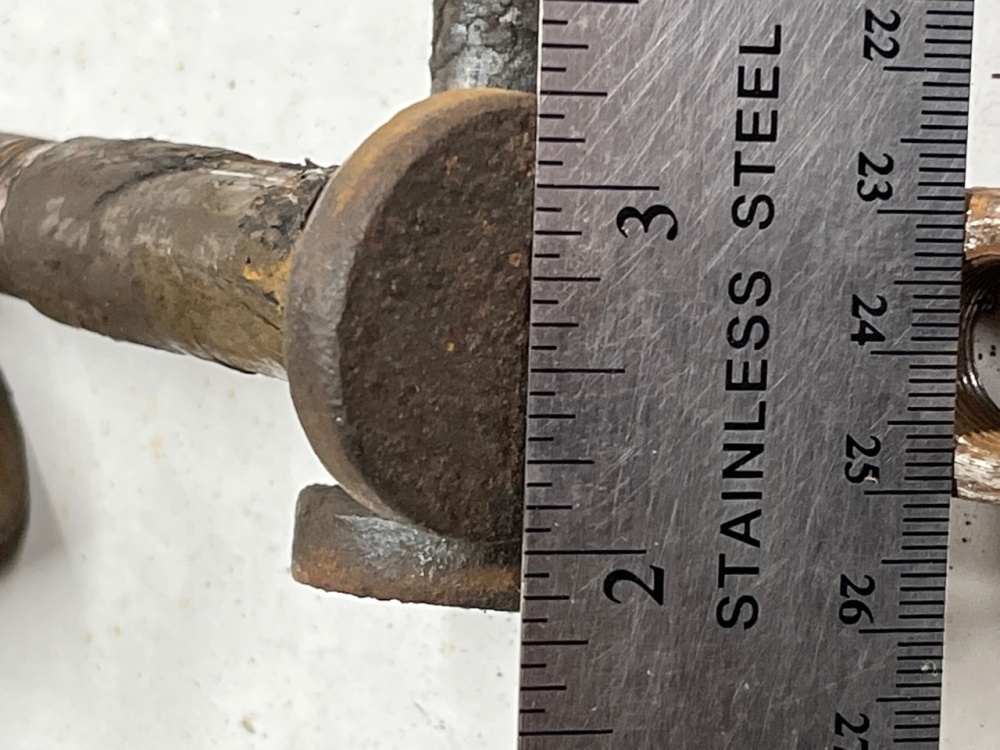

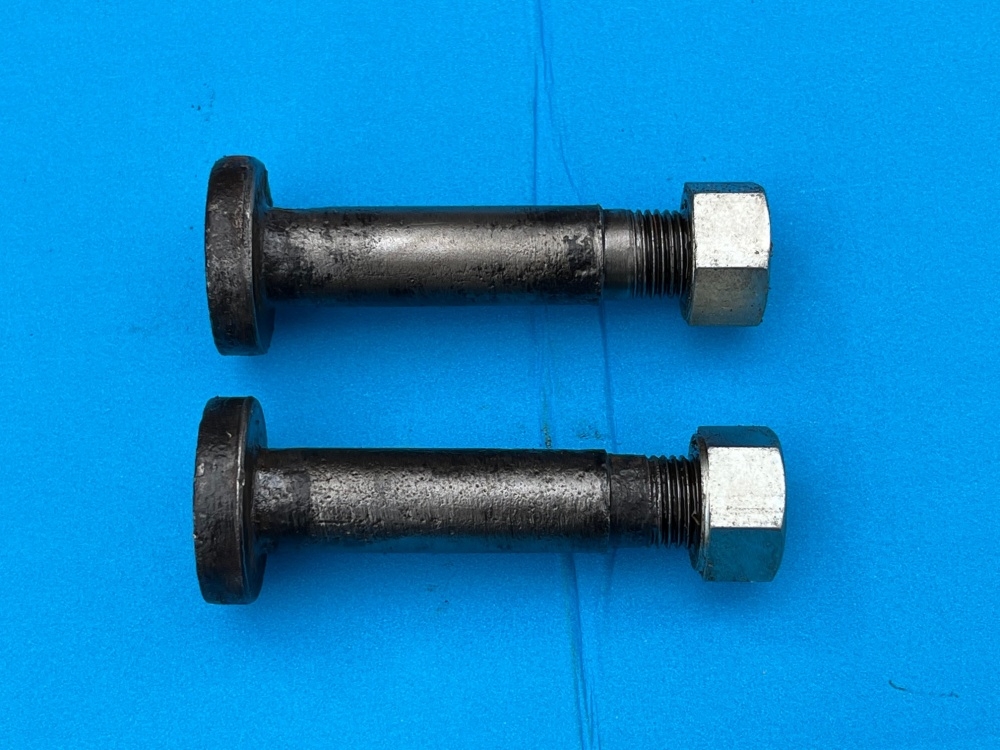

Pictures of the bolts -

0 -

Hi Rick, shall I make you a pair of new bolts? I am a retired machinist in SLC, UT. You can send me a PM or reply here. Gert (HET member since March 1968)0

-

0

-

-

That's what the rear shackle looks like. Odd That there is nothing in the description concerning 'left' or 'right' - It is my understanding that the individual shackles are also unique to the left or right side of the vehicle, one of them being 'reversed' threads on the shackle (so the shackle doesn't 'back out' with the movement of the suspension & springs). I actually experienced this, when attempting to remove the left-rear shackle, which had/has the reverse threads (righty-loosey, lefty-tighty)..onerare39 said:

However, at this point I have some generic replacements coming from Eaton Detroit Springs (no ETA, as yet). I've even managed to find nuts for those unique bolts at a local ACE Hardware (threads are = 9/16 X 18).0 -

Bolts, cleaned up with a wire brush-type wheel, and new nuts (9/16 X 18)

Actually did this, a couple of weeks ago - found it had not been 'posted', when I went in to do an update on this particular 'mini-project' ('small bites' theme)..0 -

Got both rear leaf springs disassembled & cleaned. Took a lot of time, and although there was a LOT of rust (in some places (surface layers of rust falling off in thin chunks of rust and dirt) and obvious wear in areas, they appear to be solid.

Observations - Hudson wasn't to concerned with 'finish' on these springs. While cleaning, I have noted that the ends (where they were cut-to-length) on the leaves were not deburred, or, in some cases, not even really cut 'straight' - LOL! Looks like more of a guillotine-type of cut rather than a saw-type cut, which makes sense in the mass/quantity manufacturing process.

I mention this, as I squared-up the edges and rounded-off the corners with an angle grinder while I was at it

More to be done with 'fit and finish' on these while getting ready to paint - which should happen in the next few days. I'm also 'prepping' differentials for paint - plan to paint both, at the same time. Will post pictures, as it progresses..0 -

'Clean-up' day in the workshop - putting tools back where they belong, sweeping up, and putting parts & pieces in some type of order (or at least a place where they can be found).

While I was at it, I took some photos of the replacement bushings & shackles (from Eaton Detroit Springs), putting new/old side-by-side. Here they are:

First and second photos are the shackles - Not what I was expecting, these look like the originals -

Looks very similar, or the same. Even have left-handed threads..

I have saved the best for last. These appear to be the same diameter (ID / OD), however are a bit longer, with a MUCH larger lip (more discussion, below):

The receipt says part no. 'HB-862'. A cursory check online finds that these are 2" Harris Bushings, for a Chevrolet truck.

Looks like the larger 'lip' needs to have about 3/16 - 1/4" shaved off, and the bushing area about the same as well.

Seems like this should be simple (?). Anyone ever tried to 'cut down' a hard rubber bushing?

0 -

Oh - FYI.. If you need those 'HB-862' bushings (and figure out how to easily cut them down), Eaton Detroit Springs sells them @ $4 each, + shipping.

Just found them online (by part number, $4.95 for a set of four, plus shipping) here:

https://www.sdtrucksprings.com/bushings/harris-leaf-spring-bushings

0 -

Thanks for sharing all the information and pictures. I have been wanting to rebuild my springs also.

0 -

Put a bolt thru the rubbers, use nuts and washers and mount in a lathe chuck0

-

Was thinking along similar lines - no lathe to mount them into, don't know anyone (locally) that has one.barrysweet52 said:Put a bolt thru the rubbers, use nuts and washers and mount in a lathe chuck

Am mulling it over, trying to come up with something..0 -

Might put a wooden dowel through hole and use bench grinder to reduce length - primitive and dusty - wear a dust mask. Could also freeze them - plastic bag to keep away from food in your freezer. This should harden the rubber and make it easier to grind. I made a set of 1929 Hudson shock absorber rubber bumpers by altering rubber stoppers from a chemistry supply house and shaped them on a bench grinder stone.

Also stinkey. Gert0 -

Hello,

Are you sure the new ones are longer? The old ones have been compressed over time.

Take care,

Steve Bryson0 -

I used a band saw on hard rubber bushings. Regards, Tom0

-

Piece of dowel through the middle and a very sharp knife. Use soapy water as a lubricant to stop the rubber grabbing onto the blade.0

-

Hi Steve - Yes. The only two dimensions that are correct are the ID & OD. Per the online specifications for the 'HB-862' bushings, they are made for a 2" Chevrolet truck spring. Since these are 1 3/4" springs, this means the length is off (too long) by 1/4" of an inch total (or 1/8" per side/bushing).stbryson said:Hello,

Are you sure the new ones are longer? The old ones have been compressed over time.

Take care,

Steve Bryson

I am unsure how much needs to be removed from the 'shoulder'. I am going to go up, under the truck, and measure the 'mount' it goes into - as you say, they are 'compress-fitted', so are expected to be 'snug' when installed.

Guess we'll see how this goes - Have some ideas on 'simple' methods of cutting, and it appears that it will be a case of 'whittling' them down, a little at a time..0 -

Ok - Did a 'test fit' of the cleaned-up leaves, with the leaf liner. It is a generic leaf liner, widely available - 1 3/4" X 20' roll - I needed an entire 20' roll for this leaf spring. Notice the screw driver, temporarily in place to align the leaves. It will eventually have a 3/8" X 4" center pin bolt, and I will probably need to trim off any excess. Leaf liner is installed with the edge/lip facing down, so as not to retain or accumulate any moisture/water. Notice all the wrinkles in the leaf liner, going across the springs -

This is of the leaf retainers (to keep them in-line & in place). Note the space, due to removal of four (4) leaves (the bolts are 5/16" X 2 1/2")..

This leaf retainer is farther toward the bushing & shackle ends. Not as large a gap -

When I cut out the old bolts, they had a roller/spacer. Putting one of these in (cut from 3/8 ID pipe) makes it appear more acceptable - maybe. It's either that, or 'filling-in' the holes (welding), and then re-drilling.. Any thoughts on this?

Pulled out the heat gun, ran it over the rubber 'leaf liner' edges very carefully, watching very, very close (didn't want it to melt). It laid flat, and stayed that way. Let it cool, did the other side as well -

Leaving it in the clamps overnight, then will pull it apart, do what I need to - to those leaf retainer clamps (?), cut off excess, clean it up, paint it all, and put it back together..0 -

Fill the holes and redrill. Leave no more than a 1/16" gap between the spring and the bolt.0

Categories

- 36.6K All Categories

- 85 Hudson 1916 - 1929

- 11 Upcoming Events

- 73 Essex Super 6

- 28.4K HUDSON

- 511 "How To" - Skills, mechanical and other wise

- 989 Street Rods

- 150 American Motors

- 170 The Flathead Forum

- 47 Manuals, etc,.

- 71 Hudson 8

- 40 FORUM - Instructions and Tips on using the forum

- 2.7K CLASSIFIEDS

- 592 Vehicles

- 2.1K Parts & Pieces

- 76 Literature & Memorabilia

- Hudson 1916 - 1929 Yahoo Groups Archived Photos