Dual brake master cylinder

Hello has anyone changed their master cylinder on a 46/47 super six with a dual set up. I know Speedway Motors has a few with the brake arm assembled. Has anyone used them before thank you!!!!

0

Comments

-

I did on my 41, when I did the front disc brake upgrade. I made a 3/4" thick adapter that bolted to the factory mount on the frame and had two studs on it to mount the new master.0

-

I did a similar adaptation with my jag xj6 disc brakes/suspension using the jag master cylinder and an aluminum adapter to mount the master cylinder in the stock location to use the Hudson brake pedal assembly. I also have a remote reservoir for ease of filling0

-

I believe that mid 60s Jeeps that used under floor MC will fit, but not sure.0

-

Here is some info from the Studebaker tech site. There is also a link to Turner Brakes that make disk brake kits for Studebakers, but also sell a bracket to mount dual circuit MC under the floor https://www.formstack.com/forms/?1472925-Z8mwvGr2wT:

TURNER Dual Master Cylinder Bracket

(15) Installing a Turner Dual Master Cylinder Bracket (left) allows you to replace the Studebaker single circuit master cylinder with an, up to date,

Installing a Turner Dual Master Cylinder Bracket (left) allows you to replace the Studebaker single circuit master cylinder with an, up to date,  dual circuit, master cylinder, which goes al long way toward improving safety in your car.

dual circuit, master cylinder, which goes al long way toward improving safety in your car.

In a dual circuit system, if either one of the circuits get damaged, you can manage a safe stop using the other circuit.

Installation instructions come with a list of recommended master cylinders, to use on the bracket. Others have been found, with nice features, including remote fill capabilities. The things you have to remember, is that

1) these recommended master cylinders were used on applications other than Studebaker, so they have to be modified.

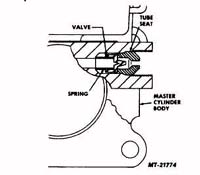

2) none of them were designed to be installed under the floor, of a Studebaker, so there may be issues that were not found initially. One of these issues involves the filler cap on some MC's, others involve the MC contacting a body brace, or crossmember.The one item that is a sore spot and never understood, are residual valves. These are small rubber check valves, installed on ALL drum brake systems to maintain a certain level of fluid pressure in the brake lines. Turner's kit comes with Wilwood Residual Pressure valves. Depending on your application, you have to install a 10# valve on the lines to drum brakes and a 2# valve on lines to Disk brakes.

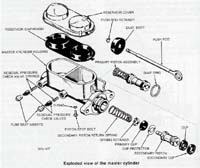

To modify ANY master cylinder, you have to open the unit and inspect if there are small rubber valves mounted in the line ports. If there are, they HAVE TO BE REMOVED and the unit reassembled with out them.

Here is a web page that describes how to accomplish the removal of residual valves ----->(16) After you have modified the master cylinder, you have to "Bench Bleed" it, before installing it on the car. This entails placing it in a vice and connecting the line ports to the reservoir, then slowly pumping the unit with a blunt tool to emulate the brake pedal action. This will replace all the air in the unit with brake fluid, prior to installation and helps greatly in getting the brake lines bled on the car.Install the unit and then, plumb the NEW (Turner) residual valves as close to the master cylinder as possible.

After you have modified the master cylinder, you have to "Bench Bleed" it, before installing it on the car. This entails placing it in a vice and connecting the line ports to the reservoir, then slowly pumping the unit with a blunt tool to emulate the brake pedal action. This will replace all the air in the unit with brake fluid, prior to installation and helps greatly in getting the brake lines bled on the car.Install the unit and then, plumb the NEW (Turner) residual valves as close to the master cylinder as possible.

Remember, even if you have a remote reservoir, above the master cylinder, AND front disk brakes, it's a good idea to install a front RPV. However, no matter what, you DO NEED to install a 10# RPV for any Drum Brake setup.

To facilitate your new master cylinder and residual valve installations, you can purchase small lengths of, easily bendable brake line and unions, at your local parts store. It will look very professional and sanitary when you're done.

Variations on the theme

(17)

You have drum/drum brakes and want to improve things..............

The first thing you should do, is inspect your components, to see if you have a power brake pedal, and if so, swap it out for a standard pedal. No other ONE thing will assure you more safety than that long pedal.

Hydrovacs work satisfactorily when they are in good shape and maintained well, or if they have been rebuilt by a reputable shop. To those of you who swear by a Hydrovac, I won't argue your position, but for 45 years, my observation, is that "I've never met a Hydrovac that I liked".

It has often been stated that you do not need a hydrovac to have good brakes. You certainly cannot have good brakes if you have a marginal Hydrovac and/or a power brake pedal.

If you install a dual circuit master cylinder, the Hydrovac can only feed one of the circuits, since it's only designed for one.(18)

You can also install a Turner dual Master cylinder Kit and upgrade to a late model dual circuit master cylinder. If you install a dual master cylinder and want to keep your Hydrovac, another possibility is the use of a combination valve. Combination valves are designed to balance your brake line effort and meter pressure. The nice thing about these is the fact that they allow your rear wheels to start braking first, then allow the front lines to apply. This creates a very smooth stop, with no nosedive, especially in a panic situation.

The plumbing solution here would be to run the front and rear lines from the dual MC to the Combo valve ports, then out to the Hydrovac for the front brakes and an unassisted line to the rear wheels. The front brakes do 60-70% of the braking and they can use the Hydro assist more than the rears.0 -

Thanks guys i appreciate your help0

Categories

- 36.6K All Categories

- 85 Hudson 1916 - 1929

- 11 Upcoming Events

- 73 Essex Super 6

- 28.3K HUDSON

- 511 "How To" - Skills, mechanical and other wise

- 989 Street Rods

- 150 American Motors

- 170 The Flathead Forum

- 47 Manuals, etc,.

- 71 Hudson 8

- 40 FORUM - Instructions and Tips on using the forum

- 2.7K CLASSIFIEDS

- 592 Vehicles

- 2.1K Parts & Pieces

- 76 Literature & Memorabilia

- Hudson 1916 - 1929 Yahoo Groups Archived Photos