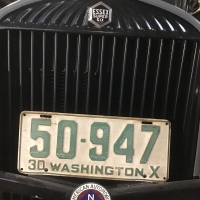

1930 Super Six Vacuum Tank questions...

The Stewart Warner tank was gutted and housed a 6v electric fuel pump, but I am now restoring the vacuum tank back to original. It is a four screw top and I believe I have all of the necessary parts with the exception of the inlet fuel filter. There is some reference to a “Vacuum Boost” but I do not know what it is. The float needle valves work under vacuum but still seem to bleed off after a few seconds. There is also what appears to be silicone in the hole under the windshield vac fitting. (See pic) That can,t be correct. There is also a small 1/4 hole drilled in the side of the top cover flange, This does not seem correct (see picture) is it? Is there any type of tank sealant that would be impervious to gasoline and would it be wise to use it on the interior Components (excluding float and needle valves) of the tank? It appears there may have been some type of coating on the float sleeve but there was also some surface rust on the walls. Is there any type of gasket for the float cylinder? Or would I be better off just scrapping the whole thing and looking for an eight screw tank? Also I cleaned and adjusted my marvel VE carburetor and after five days of sitting, the air valve was stuck again. I have cleaned and polished the plunger and the walls of the adjuster screw so there’s no build up Or corrosion. just curious to what’s happening with that air valve. Modern unleaded fuels? Thank you in advance for your help and information  p

p

p

p

0

Comments

-

The Marvel carbs are pot metal and can do funny things after nearly a century!My air valve was sticking as well. The curved spacer block has a minute crack and it had expanded by only a few thousandths of an inch. A judiciously used mill file removed the offending metal from the spacer and freed up the valve. I also polished the little piston and cylinder. Even a little dust can cause brass to stick.

Looks like you have a nice armless four bolt canister with brass fittings! Some were pot metal. They are mysterious but beautifully simple. The biggest issue is stress cracks in the nickel plated brass floats.Buy yourself a sheet of 1/8” cork and make yourself some new gaskets. The orifice in the top vacuum/wiper connection was also a head scratcher for me. It’s supposed to be there, always sucking air and creating a Venturi effect. An Allis Chalmers tractor sediment bowl screen and rubber gasket are a perfect fit as a replacement.

I have been using a product called “Seal All” for fuel related components for years. I couldn’t get my hand on a fresh tube so I tried the permatex fuel resistant blue sealant. While it is transparent, looks and smells like Seal All, it doesn’t seem to be as hardy. When I removed the glass bowl after a week of curing, it released and the screen and gasket fell out without my knowledge. I had fun trying to get it to re seal, with no gasket at all and almost succeeded! I went ahead and cut out a slightly oversized cork gasket so that it binds up against the sides of the recessed surface the bowl is located in. Next time I remove the bowl, it shouldn’t fall out again, even without pookie. I will be sure to pay closer attention to it next time. Flare fittings don’t need pookie, and all threaded fitting should have yellow Teflon tape formulated for gas.I started off manually filling the canister with fuel and leak checking it that way, allowing the engine to run on about a quart at a time. The canister fooled me initially. After the sediment bowl filled, the small compartment In the bottom of the canister had a large bubble trapped inside, preventing the carburetor from filling. I simply blew into the top of the canister, forcing the bubble past the “trap”.

This May have happened because I was leak checking and only adding very conservative amounts of fuel at a time. The level in the tank is higher during normal operation so possibly it would overcome the bubble trap. It sure flummoxed me for a while! If your carburetor isn’t getting fuel even with some in the canister look for a bubble at the top of the glass bowl.

once I piped up the sealed canister to the fuel line I ran it off a gas can straight into the fuel line and once the main fuel tank was back in it was jus a matter of hooking it up.I have noticed that the idle seems to change slightly when the canister is gulping up fuel from the tank.

The vent hole in the side of the outer canister is also by design, keeping the outer tank at atmospheric pressure.

Best of luck with this fascinating technology!You can look up non ethanol fuel retailers online.Some walmarts carry it, although it is expensive.I use the foul ethanol and religiously treat it with Sta-Bil Marine additive in my old vehicles.0

Categories

- 36.6K All Categories

- 85 Hudson 1916 - 1929

- 11 Upcoming Events

- 73 Essex Super 6

- 28.4K HUDSON

- 511 "How To" - Skills, mechanical and other wise

- 990 Street Rods

- 150 American Motors

- 170 The Flathead Forum

- 47 Manuals, etc,.

- 71 Hudson 8

- 40 FORUM - Instructions and Tips on using the forum

- 2.7K CLASSIFIEDS

- 592 Vehicles

- 2.1K Parts & Pieces

- 76 Literature & Memorabilia

- Hudson 1916 - 1929 Yahoo Groups Archived Photos