Retrofitting Aluminum Cam & Crank Gears

BigSky

Senior Contributor

A fellow Hudson member was kind enough to sell me a set of aluminum gears to use on my 37 212ci engine. I was also hoping to replace the Cam thrust washer while I’m doing this, ideally with a bronze/brass replacement.

Can you guys fill me in on what parts I’m going to be needing to replace, is there anything else to do while I’m in there & does the cam need to be removed as well?

0

Comments

-

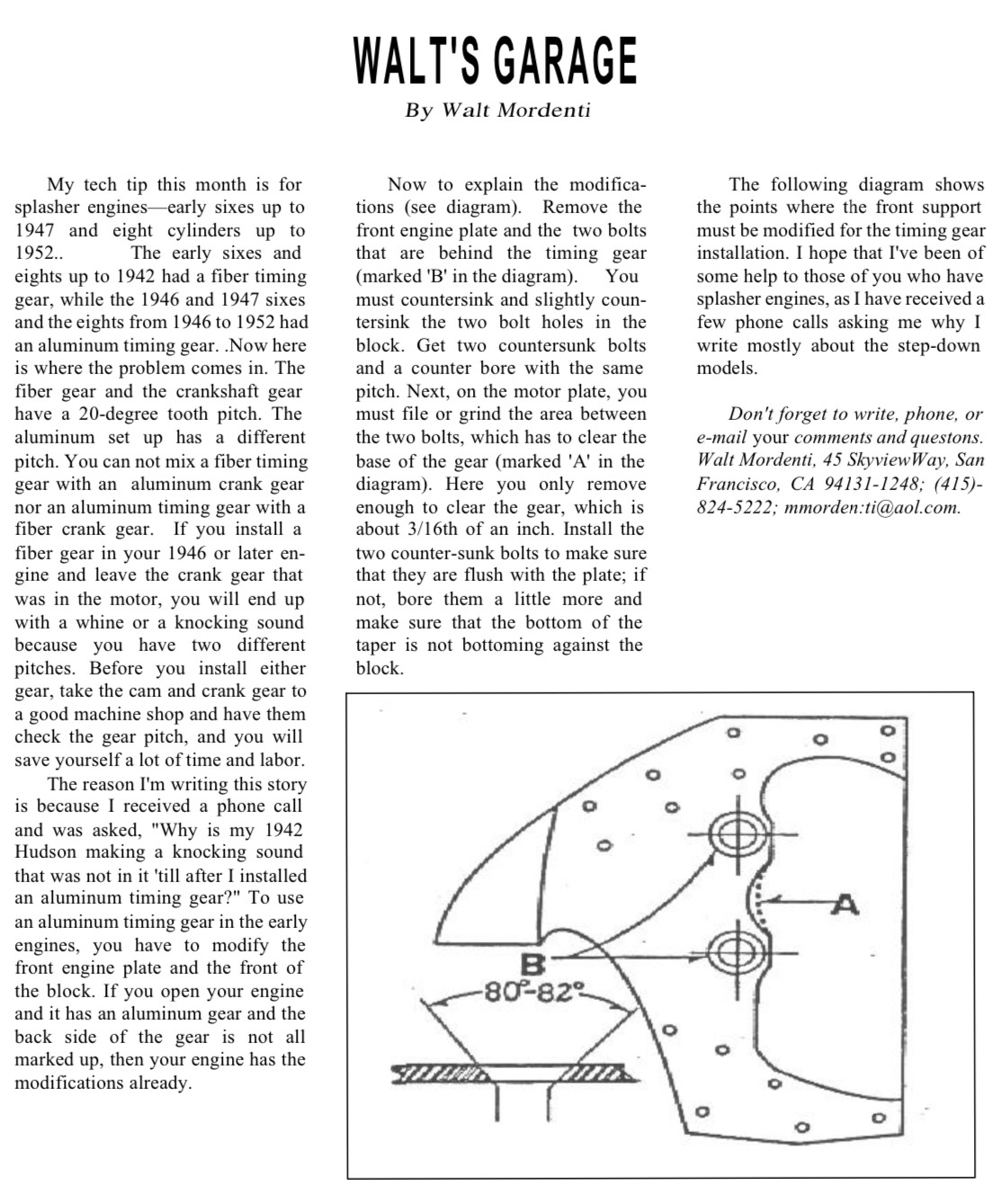

Well for one thing, the web of the aluminum gear will hit some bolt heads protruding out the front of the engine block (I have long since forgotten what these bolts connect to) so you must either replace the bolts with some with shallower heads (or flat heads), or machine a clearance slot in the gear's web. I opted for the latter solution some 40 years ago when I installed aluminum gears. The great Kelly Hinegardner very kindly performed this task for me, for which he earned my eternal gratitude.

For some reason, people say that the aluminum gears are noisier than the original fiber (I like to say "Masonite") gears but I have never noticed that. And for four decades I've been driving my car with the supreme confidence that I will never have a catastrophic failure of the fiber gear.0 -

I ran across this the other day from Walt’s knowledge base.0

I ran across this the other day from Walt’s knowledge base.0 -

The thrust washer fits between the block and the camshaft's gear boss, the cam needs to come out in order to accomplish this.

Re the heads of the 2 front plate bolts behind the cam gear. Rather than use the countersink screw method I left out the spring washers and lock tab and took a smidgen (technical term) off the bolt heads. A test fit and rotate showed nothing was colliding, for good measure after that I loctited the 2 bolts.0 -

Bob, I machined a gnat's whisker off the bolts. Soo long as you are within coo-ee it's fine.0

-

So to pull the cam, will the head need to come off yet again?0

-

Yes. It can be done without doing so, but it is easier in the end to do this. You can replace a broken valve spring without lifting the head, but to remove the cam you have to take the lifters out, or lift them high enough to clear the lobes.0

-

Geoff:

Just theoretically....if someone wanted to avoid removing the head when removing a camshaft....

If a person would simply compress each valve spring, pull out the retaining clip from the valve stem and thus release pressure on the valve lifter, could one not slide the camshaft out of the engine block? This would entail raising and securing each lifter so that it remains up. Then the camshaft could be slid out, rotating if necessary so that the highest part of each lobe was "down" when it encountered another lifter, as it was slid toward the front of the engine.0 -

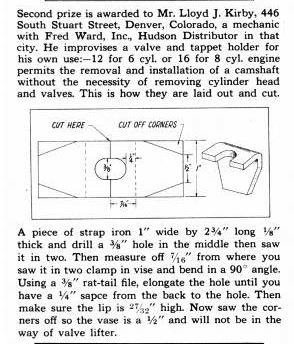

I included this Hudson Merchandiser award notice in the July issue of the SOUTH TEXAS CHAPTER HET CLUB newsletter.0 -

Yes, as I said it can be done, but by the time you faff around obtaining, or making the lifter clips, you would have the head off, valves out, and the job done. The lifters have to be hoisted high enough for the lobes to clear.0

-

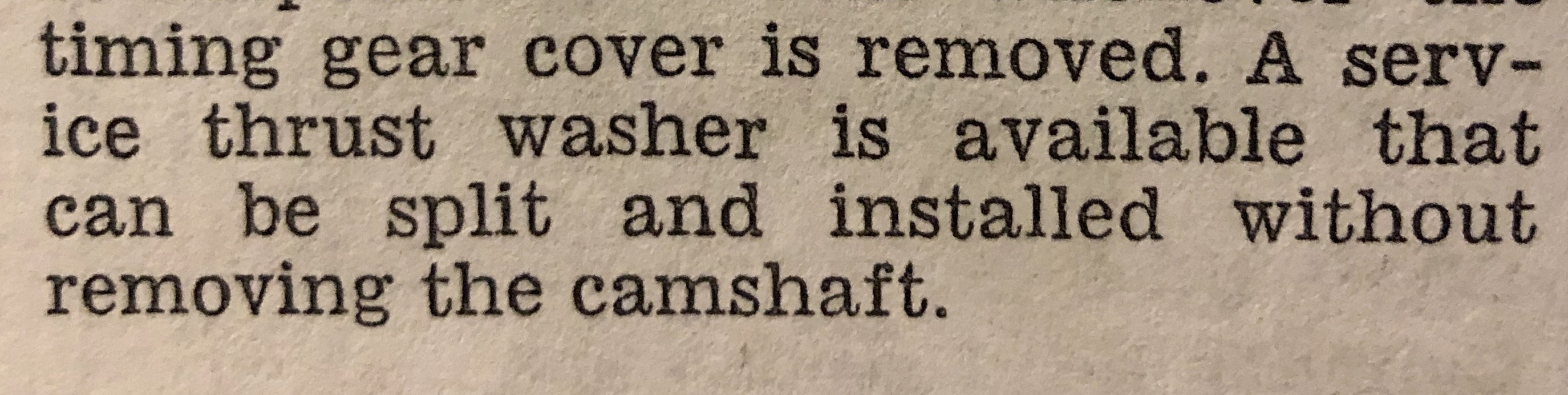

Does the cam really need to come out or is there a way to cut The cam thrust washer & slip it in place without completely removing the cam?

Also, can anyone tell me what the bolts specs are that I need to buy to replace when doing the cam/crank gear swap? In reading all that I’ve found on the retrofit it only talks about replacing the bolts but I need to know specifically what it is I’m going to go buy. Hope that makes sense, as I’ve not done this before.Almost forgot, what kind of puller do I need to remove the crank dampener? Any concerns or “be aware of’s” when doing that?0 -

The Hudson splasher 6 & 8 cam thrust washer is designed as a one piece item, if you were to cut it for convenience of installation the 2 halves would quickly work their way out from behind the cam gear and make loud noises as they went through the timing gears.

Re the 2 front plate bolts, there are 2 methods mentioned above of reusing the existing bolts, no countersinking etc required. All you need to do is reduce the height of the bolt head a little so it doesn't clash with the back of the cam gear.0 -

Yep, well aware of the problem a missing thrust washer can create with Hudson’s design.The engine only has a couple hours of run time on it since the lifters were out & cam checked during the rebuild. I doubt it’s developed a problem over that time but I’ll know more after I open the timing cover & find out if the cam thrust washer is present or not and it’s condition.I’m very eager to see the condition of the cam gear especially with the timing jumping all over the place in this video. Notice the noise coinciding with a much larger jump of timing.I did run across this in the Motors Manual, I wonder how the cam thrust washer was split & put into place as well as what it was made from?

0

0 -

split like a piston ring, with a slant cut.

there are no ears like the original, it is just round.

Hudson sold them.0 -

You just slip it in place with cam pulled forward a little to clear it.

just like winding it in place0

Categories

- 36.6K All Categories

- 85 Hudson 1916 - 1929

- 11 Upcoming Events

- 73 Essex Super 6

- 28.3K HUDSON

- 511 "How To" - Skills, mechanical and other wise

- 989 Street Rods

- 150 American Motors

- 170 The Flathead Forum

- 47 Manuals, etc,.

- 71 Hudson 8

- 40 FORUM - Instructions and Tips on using the forum

- 2.7K CLASSIFIEDS

- 592 Vehicles

- 2.1K Parts & Pieces

- 76 Literature & Memorabilia

- Hudson 1916 - 1929 Yahoo Groups Archived Photos