Removing bearings on Hudsons and Terraplanes

barrysweet52

Expert Adviser

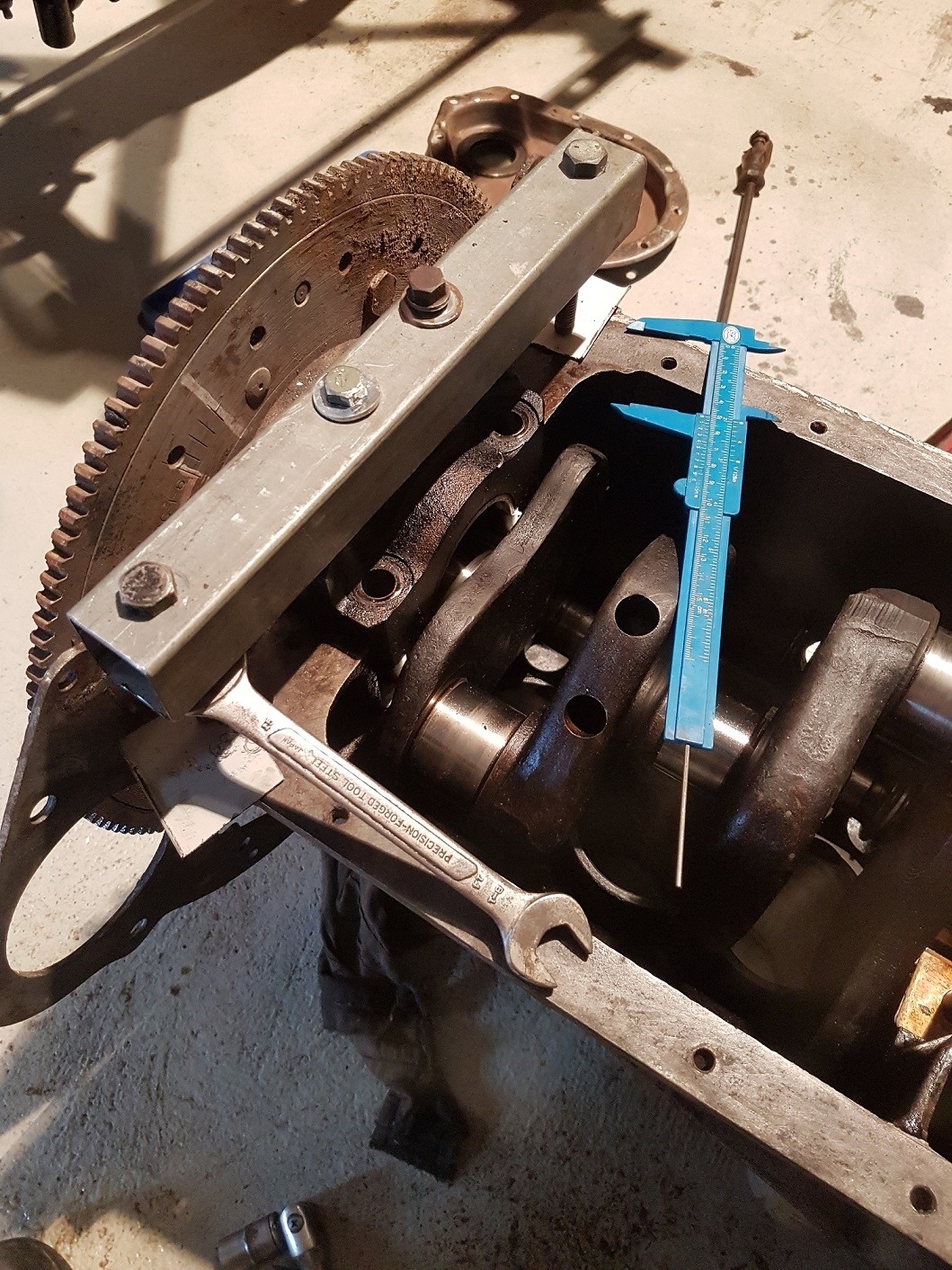

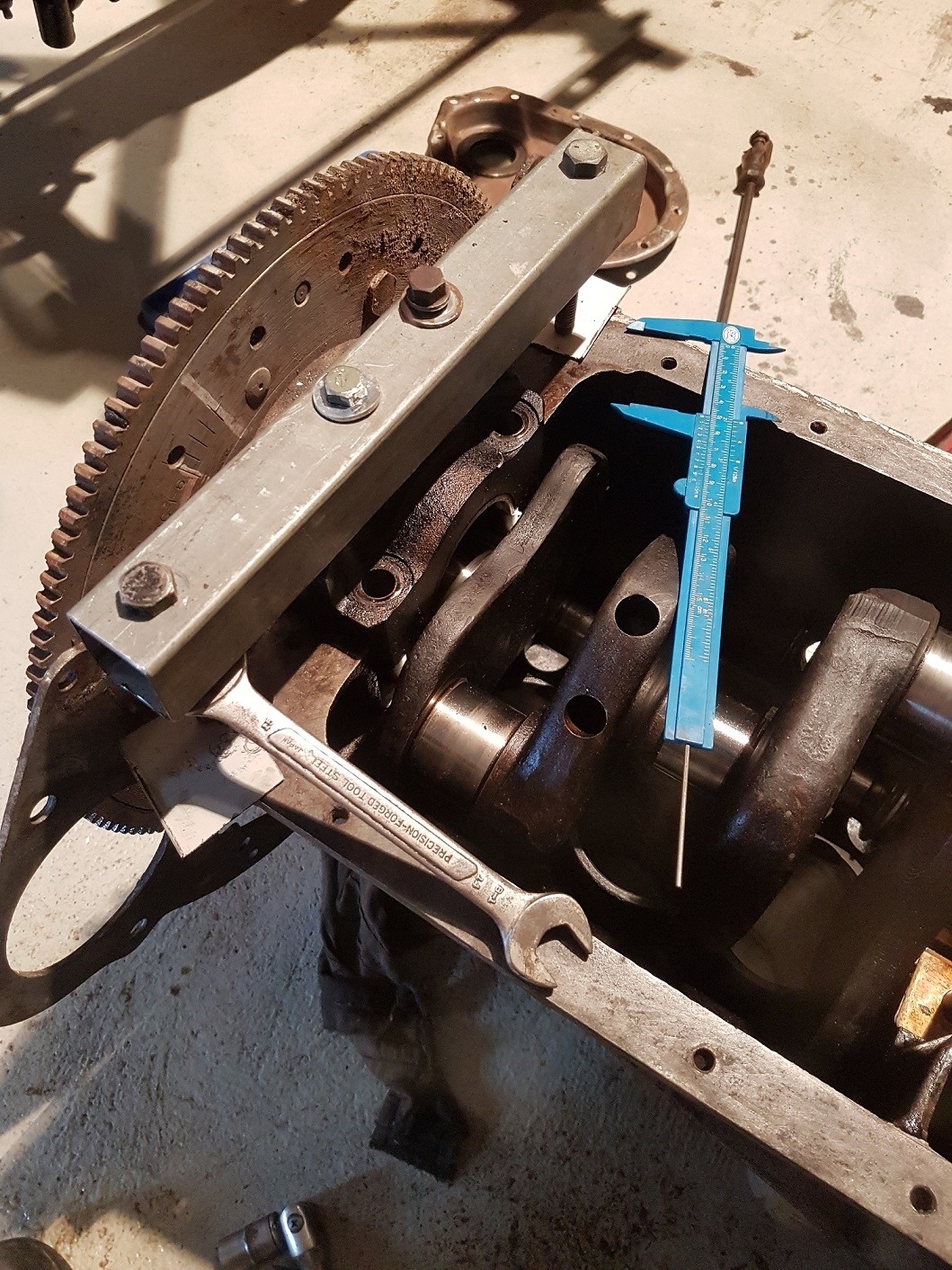

Photo shows a simple tool I have made from thick tube. Distance between front 5/16 threaded holes is different to the holes at the back. Bearing block is a tight fit so its important to pull block out vertically - I used a caliper to check the starting clearance then wound the end bolts the same number of turns. Could have welded a nut under the tube but just used a spanner. I used a scrap piece of steel under the end bolts so that it didnt damage the crankcase. I very quick easy job. Hope its of interest and will help someone.

0

Comments

-

Clever idea, thanks for sharing.0

-

Thanks for sharing Barry.0

Categories

- 36.6K All Categories

- 85 Hudson 1916 - 1929

- 11 Upcoming Events

- 73 Essex Super 6

- 28.3K HUDSON

- 511 "How To" - Skills, mechanical and other wise

- 989 Street Rods

- 150 American Motors

- 170 The Flathead Forum

- 47 Manuals, etc,.

- 71 Hudson 8

- 40 FORUM - Instructions and Tips on using the forum

- 2.7K CLASSIFIEDS

- 592 Vehicles

- 2.1K Parts & Pieces

- 76 Literature & Memorabilia

- Hudson 1916 - 1929 Yahoo Groups Archived Photos