54 Stepdown speedometer cable

But since the removal process was easy so far, might as well, try to help some folks while changing the cable.

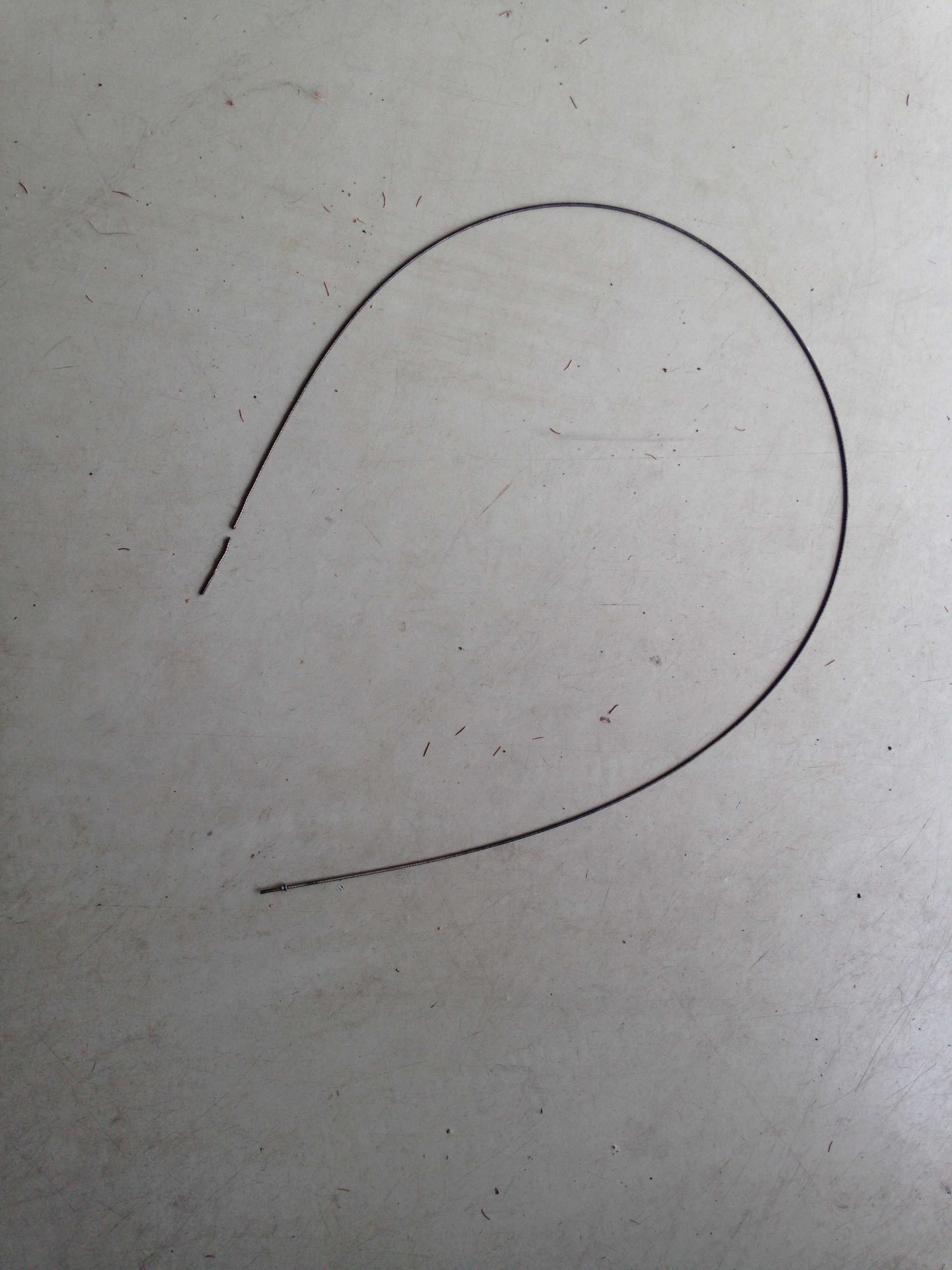

As you can see, it needs to be changed, but I've observed that the cable broke near the end that is connected to the speedometer gear located in the automatic transmission. Could the speedometer gears have slipped enough to break the cable ? Also, does changing the cable is as easy as connecting the two ends to their respective place or is it more complicated ? As always, advices from the experts are welcome.

In the meantime, I'll try to find the proper cable and give more pictures on how to change it for the club : it can be useful for someone

Thanks in advance,

Max

Comments

-

I've seen odometer wheels stick, this might be enough to break the cable, or it might not. The speedometer itself has gears inside that reduce the cable speed, and drive the odometer, it's possible for them to stick, too. But it's also common for the cable to stick because the lubricant all dried up, so it would be just the cable causing the breakage.Might want to see how the speedometer turns, by hand, before connecting the new cable. It should turn freely. If the odometer is at XX999.9 miles or something similar, then it's likely that it's stuck.Yes, all you have to do is replace the cable and insert the ends and screw on the nuts. Sometimes you have to exercise a little bit of patience to get the square tangs to align with the square holes, so you can insert the end all the way in.0

-

Thanks squirrel for the info, it indeed helped

As for the speedometer, I did removed it from the cluster as I was curious to see how it works and if it was broken.

So far, it is turning freely and seems to be still intact.

As for this part here, one end goes into the trans. driving the speedometer gear while the other end is where the cable is connected from what I've seen.0 -

Your broken cable acts as a good reminder for the rest of us to lubricate the speedometer cable on our Hudsons if it hasn't been done for a while (or not at all) and especially if it's presently making noise and/or has a bouncing speedometer needle. It really is a fairly easy job to do.0

-

Good reminder indeed. Seems one of the easy job that ignored most of the time.railknight said:Your broken cable acts as a good reminder for the rest of us to lubricate the speedometer cable on our Hudsons if it hasn't been done for a while (or not at all) and especially if it's presently making noise and/or has a bouncing speedometer needle. It really is a fairly easy job to do.

0 -

0

-

Well... I'm out of ideas.

it has been a couple of days that I'm trying to fix the speedometer cable and i'm struggling with it. Every time I thought I've fixed it, I do a road test and the cable comes free again.

This little fella is giving me the trouble as it always comes free from the cable, even when it was crimped on it ( though it could be me not knowing how to use the crimping tool that comes with the cable kit ), and I have tried many attempts to jam it tight on the cable. Right now I'm running out of ideas to fix the easy trouble that is the speedometer cable. I don't know if there's something I'm missing or done wrong, but any advices or corrections are welcome.

Max0 -

I would do some research an see if a commonly available cable and housing will work on your car. Something like a Pioneer CA3002?https://www.oreillyauto.com/detail/b/pioneer-inc--4618/transmission---transaxle-16780/transmission-parts-16520/speedometer-cable-11192/97e78494abee/pioneer-inc-speedometer-cable/ca3002/4621013?q=ca3002&pos=0I never had much luck with the crimp on ends, I just replace the whole thing.0

-

I did took the length of the cable and if I've done it right, it is a 68 inches long. I'll do some research on my side too as I really want to get it fixed.0

-

The speedometer cable ends are SWEDGED onto the flexible cable piece. Swedging the cable requires extreme force to assure the two pieces are affixed to one another.0 -

I may have an idea, but needs more data before doing it;

Does the cables themselves ( not the jackets ) are of the same diameter, regardless the car application? If not, what is the exact cable diameter Hudson used for their speedometer cable? As my potencial idea would be to get a speedometer cable that has the exact length so it would be way easier to fix.

Dang it, I would have loved to think of this sooner lol.0 -

there are only a few "universal" lengths of speedo cables available today. Unless you get one custom made (many speedometer shops did/do this).

0 -

Speedometer issue update:

I reveived the cable I ordered, but unfortunately upon installing it was too long by 2 inches. Luckly, I kept the previous cut-to-fit cable and lend it to my boss ( a good car mechanic ) to fix the tip as it should be.

After installing the cable, I did a road test... to see the speedo not moving at all and hear the cable sort of running free.

" Ah crap, here we go again..."

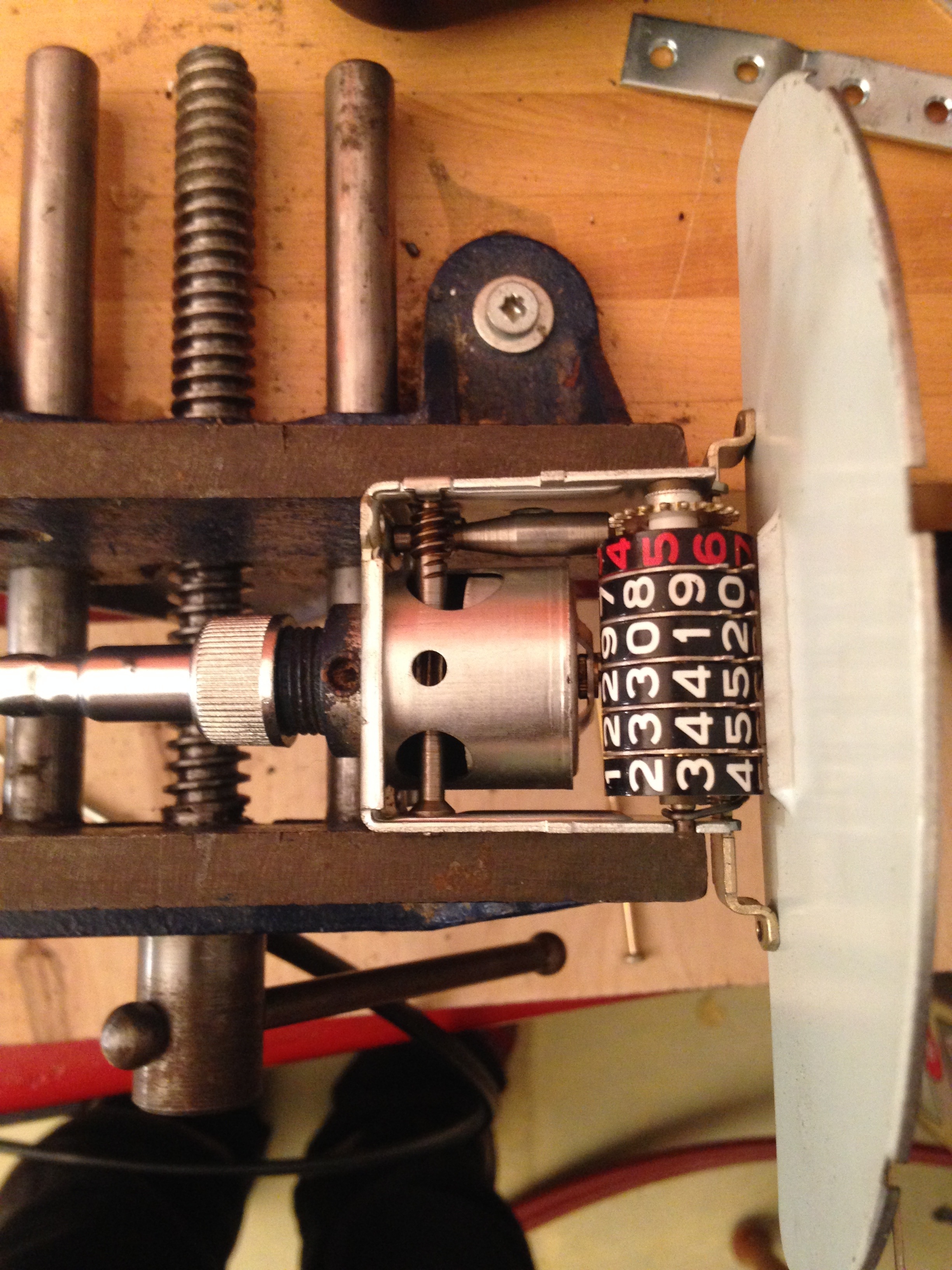

I did check the cable and to my relief, it was still in one piece. So i decided to check the speedometer itself and do some deeper tests on it. As seen here, I've sperarated the speedo from its back cover to have a good view to the interns. From here I wanted to see if I was able to turn the gears by hand by using the long speedo cable.

As seen here, I've sperarated the speedo from its back cover to have a good view to the interns. From here I wanted to see if I was able to turn the gears by hand by using the long speedo cable.

"Well, at least I haven't really bought the cable for nothing."

From the test I discovered that the problem did come from the speedo as, while turning the gears, it was turning fine for a while until it became a bit harder to finally turning fine again. there might be something in the gears that make speedo stuck.

From now on I'm asking if it is possible to save this speedo, and if yes, what would be the procedure. Any advices or corrections are welcome.

Max

0 -

Did you happen to watch the odometer while you were turning it? Perhaps the odometer had to turn a couple digits when it was hard to turn? They get sticky with age....might need to be disassembled and cleaned or lubed? but it does look pretty clean from what I can see.Did you buy a new cable assembly with a housing? or just an inner cable? I always replace the whole assembly, inner and outer, at the same time.0

-

My experience with speedos is the vast majority just need to be cleaned and lubricated with a light oil. It does not take much to get it working correctly and you don't want to contribute to a future sticking and gumming problem with to much oil. I have brought back to life the speedo on my 1910, 1922, 1946, three stepdowns and my 1960 dodge matador this way. The biggest pain was removing and install the speedos. I also use a drill connected to a broken cable as a drive. Somewhere I was reading that 1009 revolutions is the standard for a mile on most speedos. But some do vary. Lots of good info if you look around.

Jay

0 -

The odometer was turning normaly, but the speedometer's needle was bouncing when passing the hard section when turning it. I'll put some lube and see how it reacts.

As for the cable, I only bought the inner cable with the jacket to then only se the inner one as I wanted to do. I didn't wanted to change the entire cable with the housing as I was afraid to be unable to find the proper housing that can fit into the car.0 -

I've put some light oil on key moving parts of the speedo while hand turning it until it was running smoothly. After letting the oil sit during the night and doing some final checks, I've put it back to its place and made a road test. This time the speedo was finally working.

"Huzzah ! "

Though running fine, I've observed that the speedo needle was a bit bouncy, but not too much. Could this be a symptom of a future issue or was it a normal occurrance of the speedo ?

Again, thank you very much for your help, for sure I've learned alot about the speedometer 0

0 -

It could just be lubrication or lack there of with some parts still just a bit sticky. However, some speedo do use pot metal cast parts. These parts will go bad, it is just a matter of time before they swell and fall apart. I have found that many of the early speedos go through changes to the mechanics during a production run. The physical look may not change but the internal parts may. So on my 1922, I had one speedo that had pot metal parts for the odometer gears. Another identical looking unit made a bit earlier had brass odometer parts. I just swapped them out and no one will ever know.

Jay

0

Categories

- 36.6K All Categories

- 85 Hudson 1916 - 1929

- 11 Upcoming Events

- 73 Essex Super 6

- 28.4K HUDSON

- 511 "How To" - Skills, mechanical and other wise

- 990 Street Rods

- 150 American Motors

- 170 The Flathead Forum

- 47 Manuals, etc,.

- 71 Hudson 8

- 40 FORUM - Instructions and Tips on using the forum

- 2.7K CLASSIFIEDS

- 592 Vehicles

- 2.1K Parts & Pieces

- 76 Literature & Memorabilia

- Hudson 1916 - 1929 Yahoo Groups Archived Photos