How do you remove the valves?

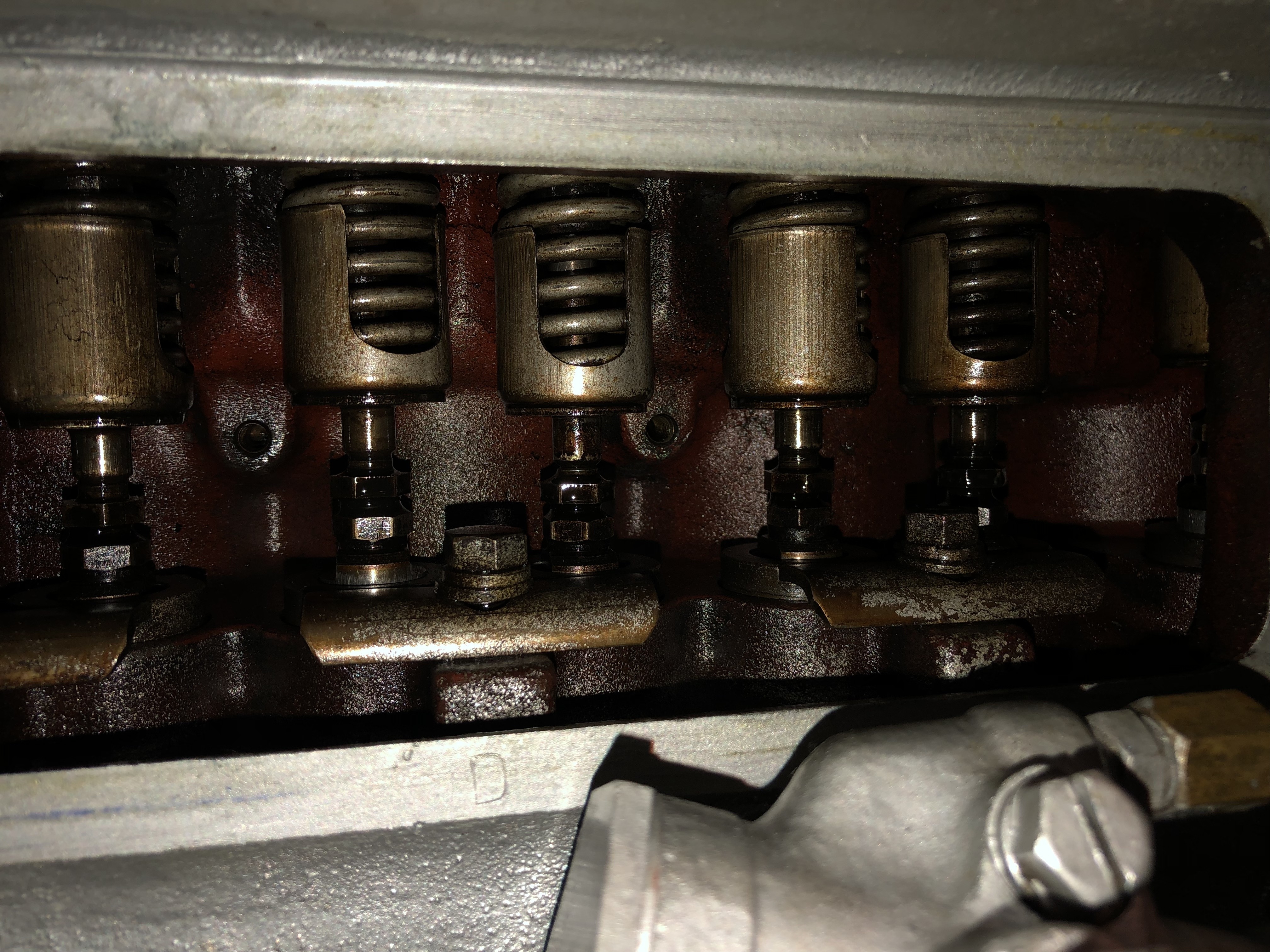

Well once again, I’ve wasted countless hours today trying to find out how to remove the valves on my 1937 Hudson 212ci 6cyl engine. There are dozens of videos & articles on the Ford Flathead but nothing that I can find for the Hudson.

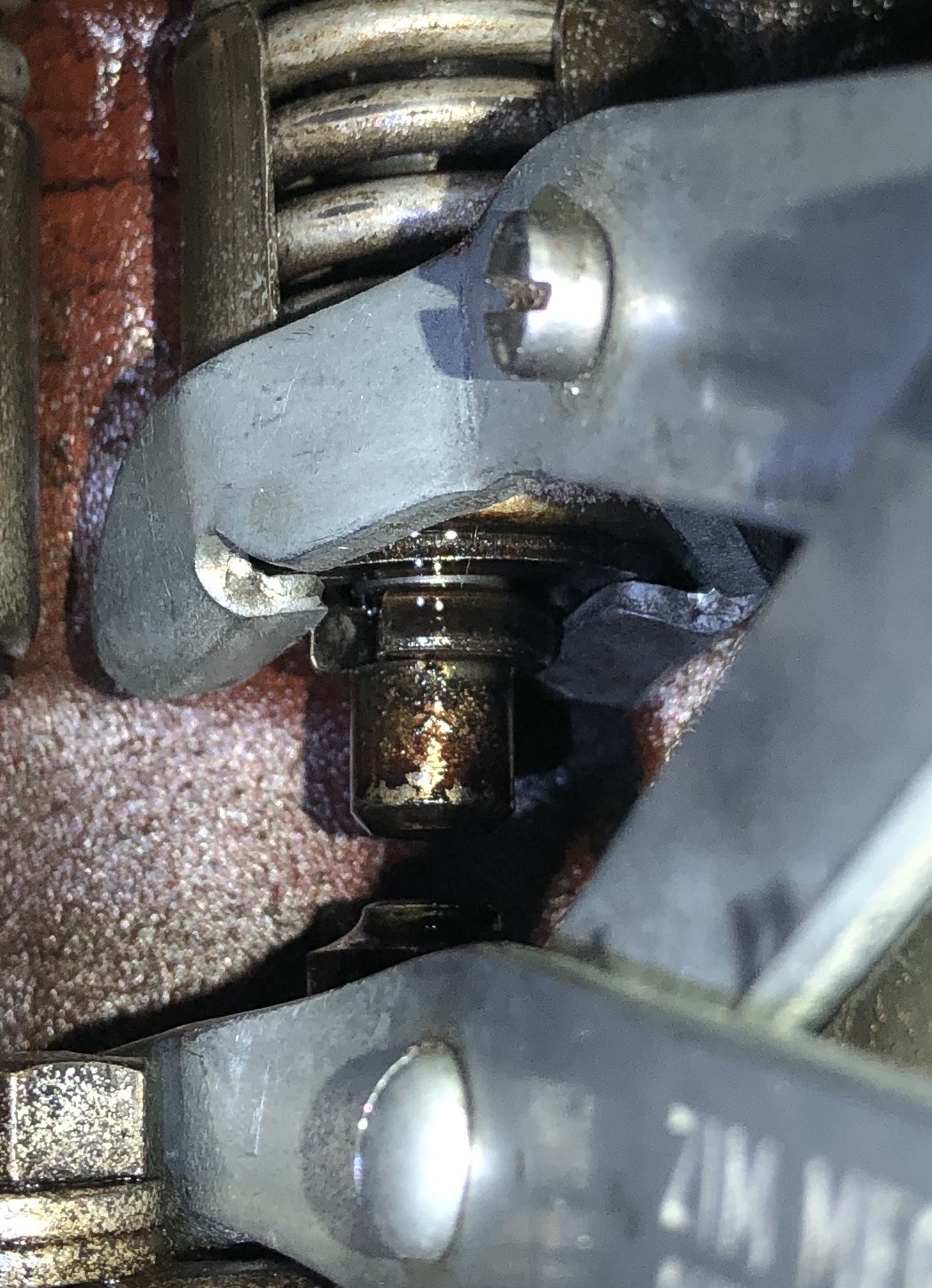

The engine has everything removed down to the block & I have a Zim valve compressing tool. What I don’t know is where do I need to put the tool to compress the spring to release a keeper or whatever it is that is locking it all together. Knowing what a part looks like helps but I’m not finding any thing that shows what the keeper (lock) looks like or how to unlock and remove it.

Can someone please help me with this?

The engine has everything removed down to the block & I have a Zim valve compressing tool. What I don’t know is where do I need to put the tool to compress the spring to release a keeper or whatever it is that is locking it all together. Knowing what a part looks like helps but I’m not finding any thing that shows what the keeper (lock) looks like or how to unlock and remove it.

Can someone please help me with this?

0

Comments

-

You simply insert the spring compressor under the retainer washer, compress the spring, and remove the horseshoe -shaped collet from the bottom of the valve stem. then lift the valve out.0

-

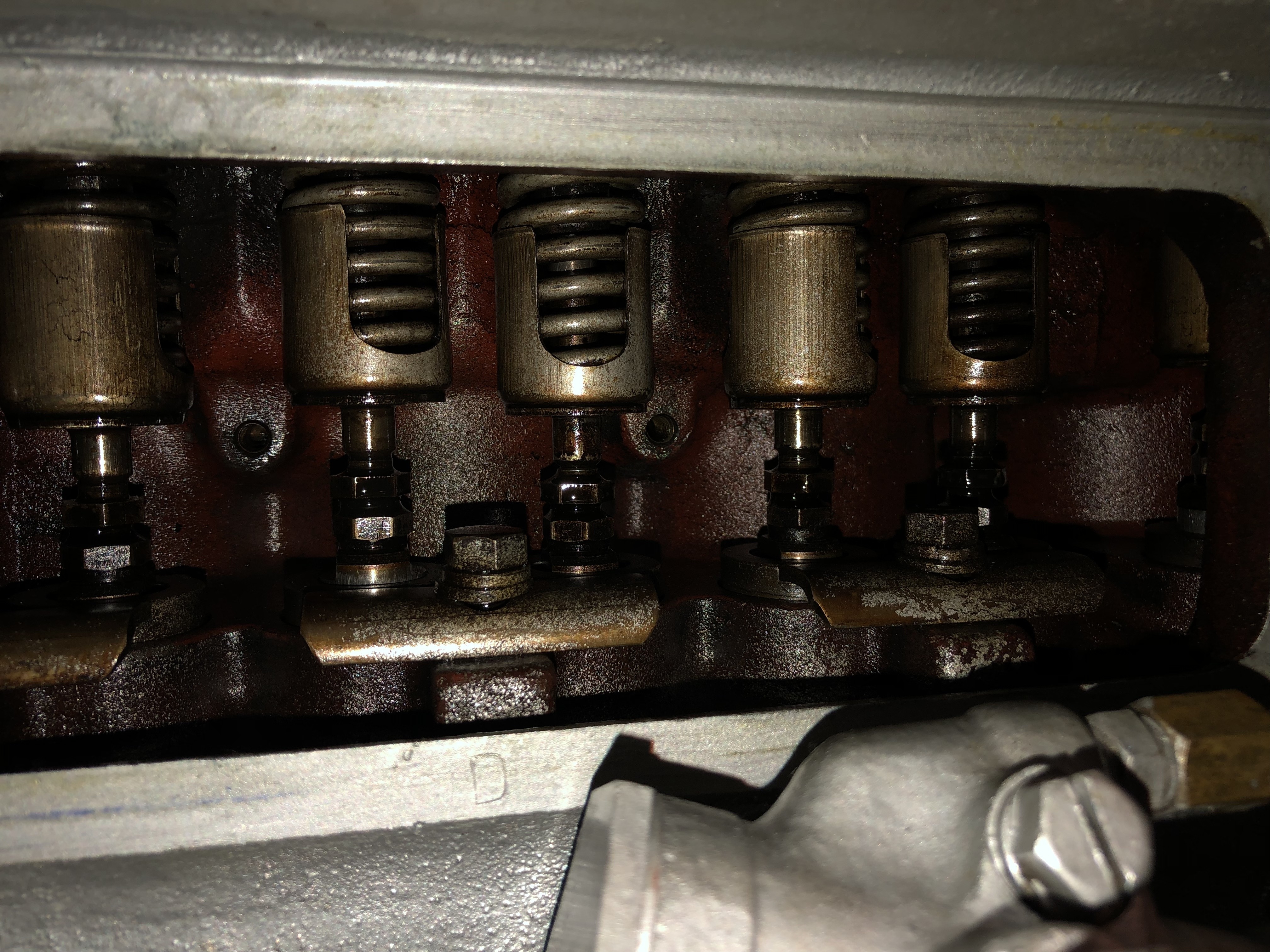

Really?!? Are you saying this big piece I have outlined in “blue” is the collet? And the washer you speak of is outlined in “yellow”? If I’m compressing these items as it’s shown in “red”, how would I pull the “blue” item out?

0 -

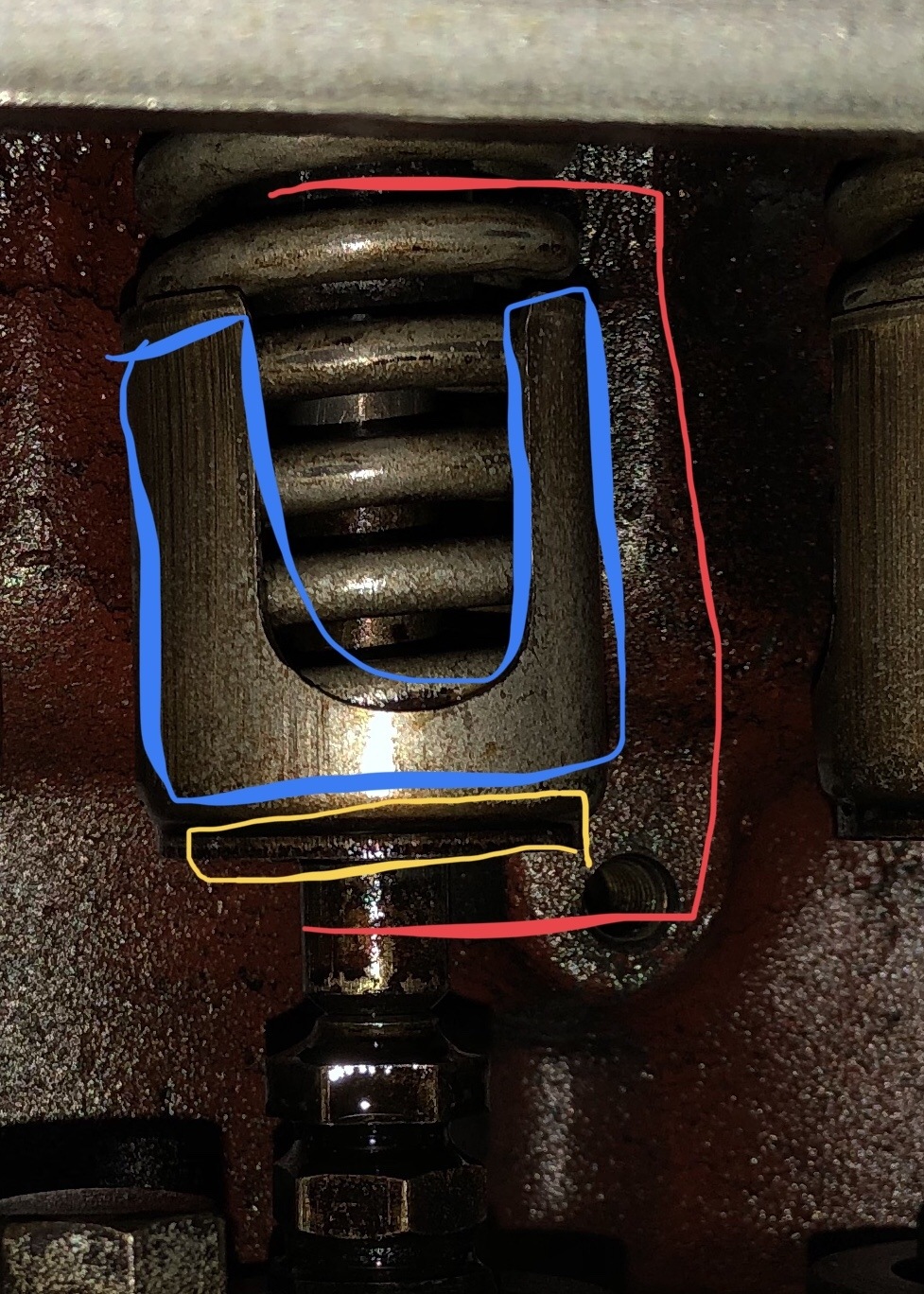

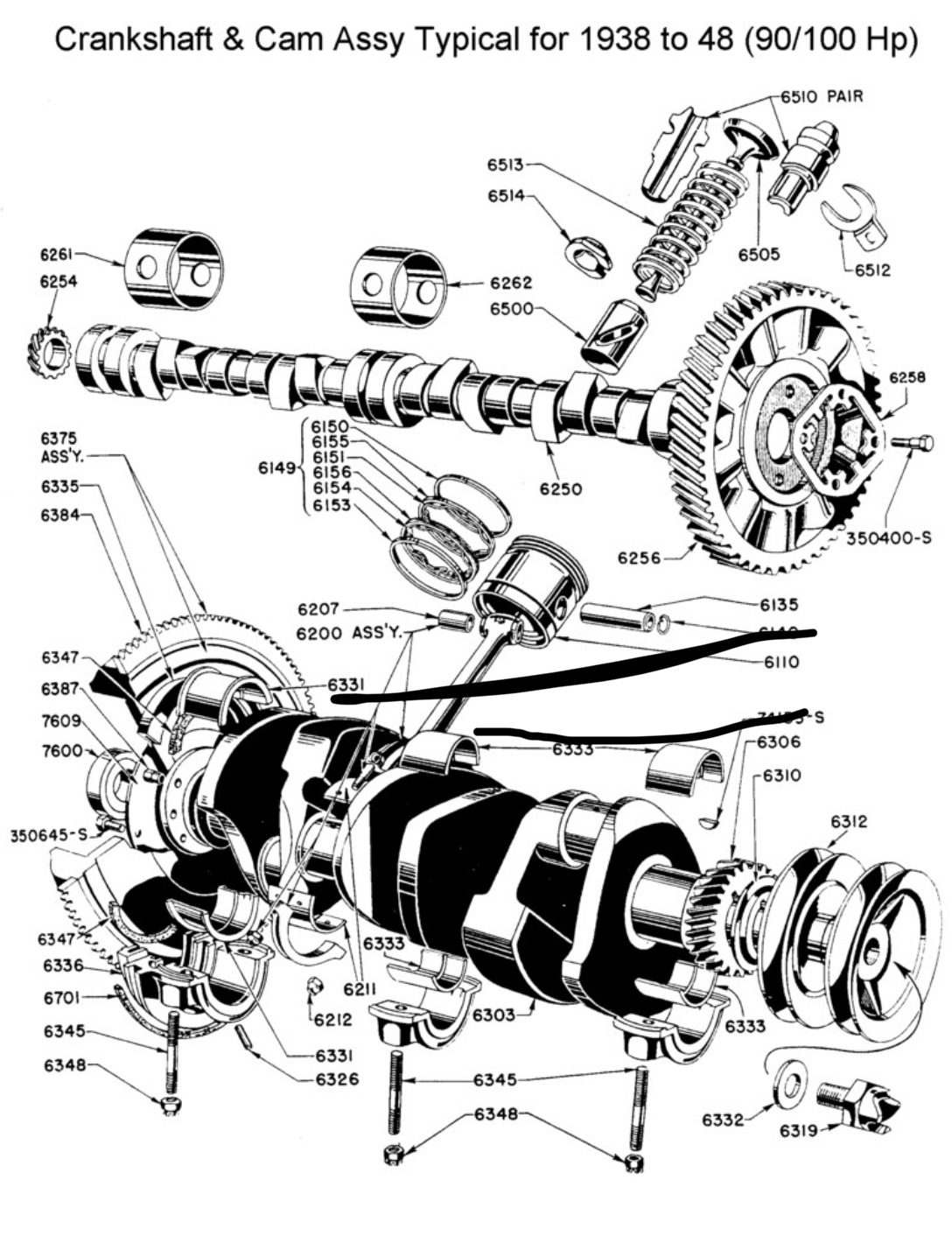

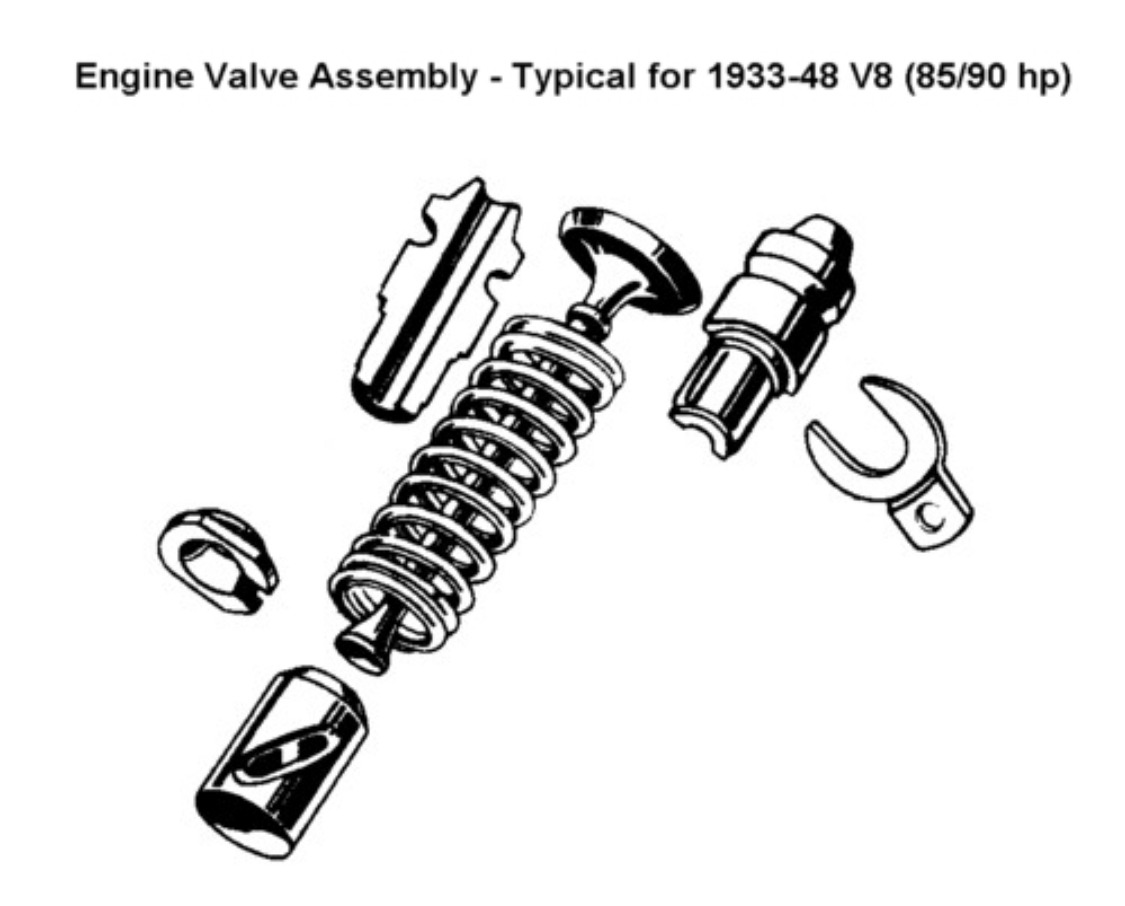

I wish there was something like this for my Hudson, below is from a Ford Flathead . It would help me understand how things go together & thus I could figure out how to take them apart!

0 -

I think the part labeled 6514 is the same type keeper as the part you have outlined in yellow. The horseshoe shaped collet is your yellow outlined part and the blue outline is the part the spring compressor pushes to release pressure on the collet. I think once it falls out, when you look at it laying flat it resembles a horseshoe but I have never had a hudson engine apart

0 -

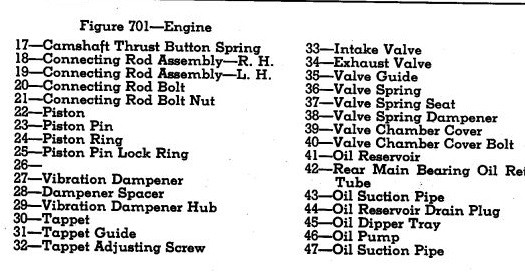

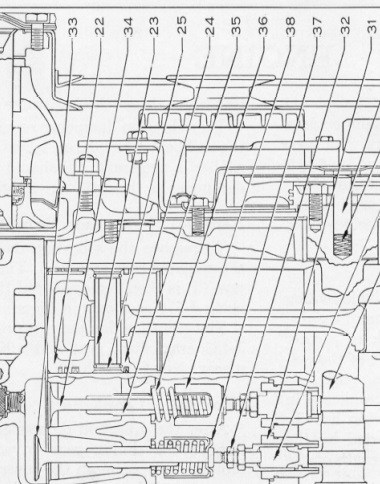

The big cup thing is called the damper, the small thing you outlined in yellow is called the seat, and is what you want to remove. you have to lift up the spring and damper, then the seat should be able to be removed, probably with the aid of a magnet. but I'm just guessing, I've never taken one of these apart!a couple pics from the shop manual

0 -

MY 37 had split keepers , two pieces that are held in place by that collar.

You compress the spring at the collar , And remove the two keepers.

You might have to clean the spring/ valve area first if you haven't already. Sometimes the gum won't let the pieces release.

Best to put rags under the valves to keep the keepers from going into oil galleys.

Check your valve guides , high wear item.

0 -

Once you compress the damper and spring it will be easy to remove the horseshoe shaped collet. Use a needle nosed pliers or a screwdriver to remove - look after your fingers. I think the dampeners were only used in 1936 or only for a few years. Be careful nothing drops down the oil drain holes. If you reuse the valves try and keep them in the same guide. Sometimes a valve could be replaced with one that has a few more thou on the stem if a guide is worn. Exhaust guides sometimes have a counterbore in the top of the guide for carbon build up. Barry0

-

I have replaced valves, and on a '37. Please see attached PDF. (Sorry, you'll have to rotate it)

0 -

How does one check the guides for wear? Is it based on how much movement the valve has at the top of the valve or ????0

-

a small dial bore gauge is the right way to measure the guides, but a snap gauge and mic will also work. The movement at the head of the valve will be greater than the amount of wear in the guide. And the guides usually wear more at the ends, than in the middle.0

-

Thanks, I’m headed out to give it a try!

Yesterday as I was searching the web for info on the Hudson’s valves, I ran across this engine build. Pretty impressive work!

http://mwengineservices.com.au/bernie-oshannesy-1938-hudson-straight-8/

0 -

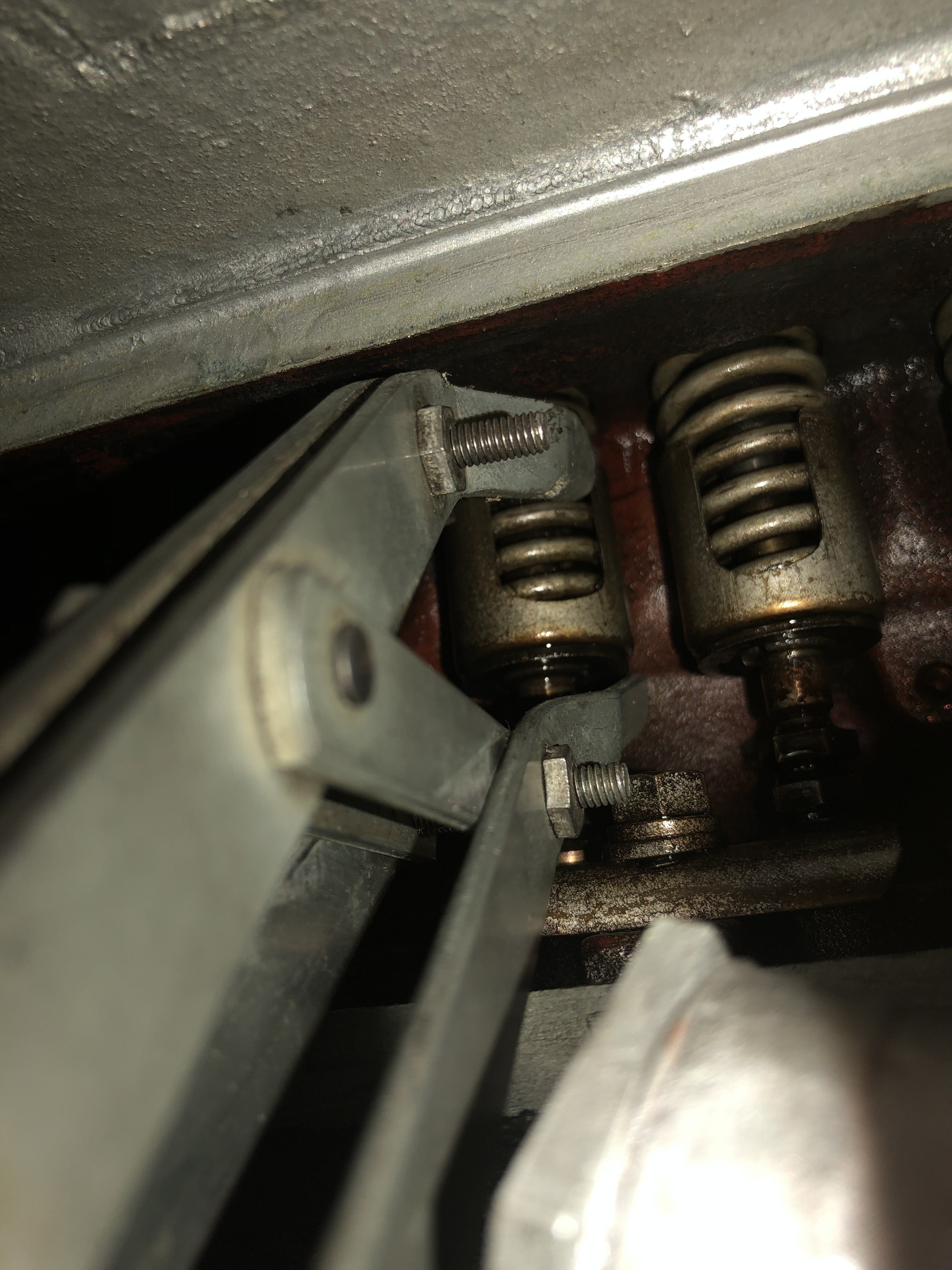

I bought the valve compression tool that the local Hudson expert recommended & give it a try. However, I can see anything so I’m doing it by feel mostly. Either way I could get it to work. Am I using the wrong kind for this engine?

0 -

I think I have a picture of the keeper, & now know what I’m trying to pull off to unlock things. Once I can find a tool to compress things....

0 -

you just have it in the wrong place. Put the whole tool beneath the spring, it will push down on a stationary part of the engine, and push up on the retainer. Looks like you found the keeper! that thing you have the arrow pointing at0

-

Correct. Wrong place. In your photo (of the valve chamber) the upper part of the tool is hooked on the spring. It should be located lower, so that it is just under the dampener. The bottom part of the tool seats itself on some solid part of the engine block or maybe the bottom opening of the valve chamber. Be sure that the upper part lifts only the dampener, NOT the retainer. You have to lift the dampener up past the retainer, exposing the retainer so you can slide it off. Be careful that the tool is properly seated as you reach for the retainer, so it doesn't suddenly let go and allow the dampener and spring to come down on your fingers!0

-

if it sounds confusing, it's because it is. It appears to me that the small horseshoe shaped piece that I refer to as the keeper is a separate piece from the larger dark colored piece that I call the retainer. Once you get it apart, you'll know for sure...we can only go by the limited amount of information in your pictures (which are actually pretty good pictures!)0

-

Ahhhh, so like this? So am I supposed to be able to just push the washer off at this point or do I need the retainer below the tool?

0 -

Tada! I had to push the valve down some & crank it up higher. The magnetic pick up tool works well. Thank you all very very much!

0 -

You got it! Congrats!0

-

Time for a beer to celebrate!!0

-

now we know0

-

Had my mechanic friend look at the valves & they are done. So new valves & guides will be in order now.0

-

how many miles are you planning to put on this engine? Keep in mind that tolerances in the 1930s are not the same as tolerances in the 2000s. You "can" replace everything on the engine....you don't "need to" replace everything on the engine.

0 -

Enjoyed following this thread Bigsky, and thanks for all the pictures. This may come in handy when I do mine on my 39 212.0

-

Don't use original 3/8" stem valves. Get new ones form Dale cooper, and guides with the later '38-'47 valves with 11/32" stems, and leave the dampeners out.0

-

I spent some time over the last couple days looking over the valves and unfortunately they are too thin at the edge & have pitted & concave mating surfaces & on almost all of them. Thus with grinding of the valve & seats to clean them up they just won’t work.

it looks like new valves & guides and probably springs are in order. As recommended swapping to the 38-47 valves & guides with a smaller diameter stem of 11/32” is the best way to go. I’m told the guides can be removed without going to a machine shop. Is there a special tool for this? When one leaves out the dampers, the loss of .035” won’t effect one’s ability to adjust valves?0 -

Next time, get a few short bolts, about 1 and 1/2" long, I think 3/8" diameter, and put one each in the oil drain holes that are in the valve chamber. The heads of the bolts need to be bigger than the drain holes. With those in place, any valve keepers etc that get dropped will not fall into the old pan.0

-

I think he still has the pan off? but that's a great suggestion, for if you don't. As long as you remember to remove them before putting the side cover back on!That valve does look pretty tired....do you know if the original retainers and keepers will work with them? and are you going to go ahead and see how good the springs are, while you're replacing all that other stuff? (removing the dampers will reduce spring pressure a bit too, although shimming the springs will bring it back)0

-

Good idea for keeping parts from dropping down into the oil drain holes & ultimately the pan. Indeed I do still have the pan off the engine.

I believe the original retainers & keepers will work with the newer 38-47 setup, but will check to be sure, as I was just assuming before you mentioned it. So thank you!

I was looking around to see if there were other valves which may work, stainless steel would be nice. It looks like lots of vehicles (Chevy, Ford) used the 11/32” stems, & I could even find some 5.300 & 5.400 length valves but I couldn’t find or determine if there were any out there with the same length tip (area below the keeper). It may very well be a huge waste of time to look at something different than what’s available but I do like to improve where I can.

Does Anyone know of a modern valve which could work with little machining, if any? I was talking with a couple friends & was told the guides can be removed & installed without the help of a machine shop which is great news. If there isn’t any other options than what’s available currently I suppose one could always message those a little too. Here’s a video from one of our members on removing the guides:

https://youtu.be/2gMBjx8fxKs

0 -

You can get new valves from Dale Cooper. If you are really keen you could stelite the original valves and reface, but this entails a lot of mucking around. You also need to remove the lifters and check them for wear, and if necessary either re-face or replace. If they are badly recess on the lifting surface you will also need to check the camshaft for wear. You can make up your own valve guide puller with a length of threaded rod that goes down through the guide. Use double nuts locked together on the bottom, and loosely together at the top so your ring spanner fits over both nuts (for strength). Use a high socket that fits over the valve hole, and a heavy washer, and screw the guide out. Leaving the dampener out won't affect the spring pressure, as you will have less inertia with the lighter valves anyway.0

Categories

- 36.6K All Categories

- 85 Hudson 1916 - 1929

- 11 Upcoming Events

- 73 Essex Super 6

- 28.3K HUDSON

- 511 "How To" - Skills, mechanical and other wise

- 989 Street Rods

- 150 American Motors

- 170 The Flathead Forum

- 47 Manuals, etc,.

- 71 Hudson 8

- 40 FORUM - Instructions and Tips on using the forum

- 2.7K CLASSIFIEDS

- 592 Vehicles

- 2.1K Parts & Pieces

- 76 Literature & Memorabilia

- Hudson 1916 - 1929 Yahoo Groups Archived Photos