Head Surfacing / Milling

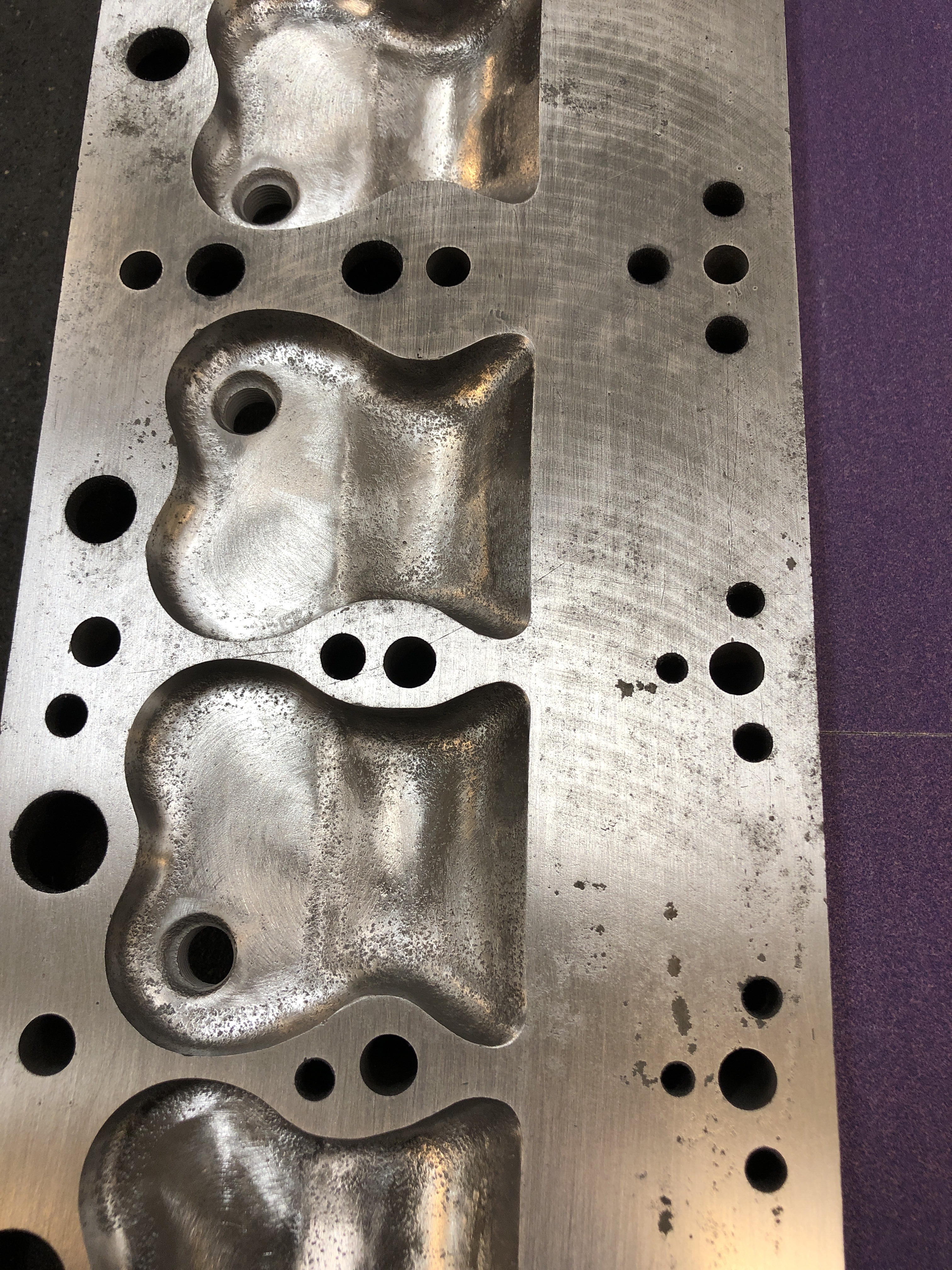

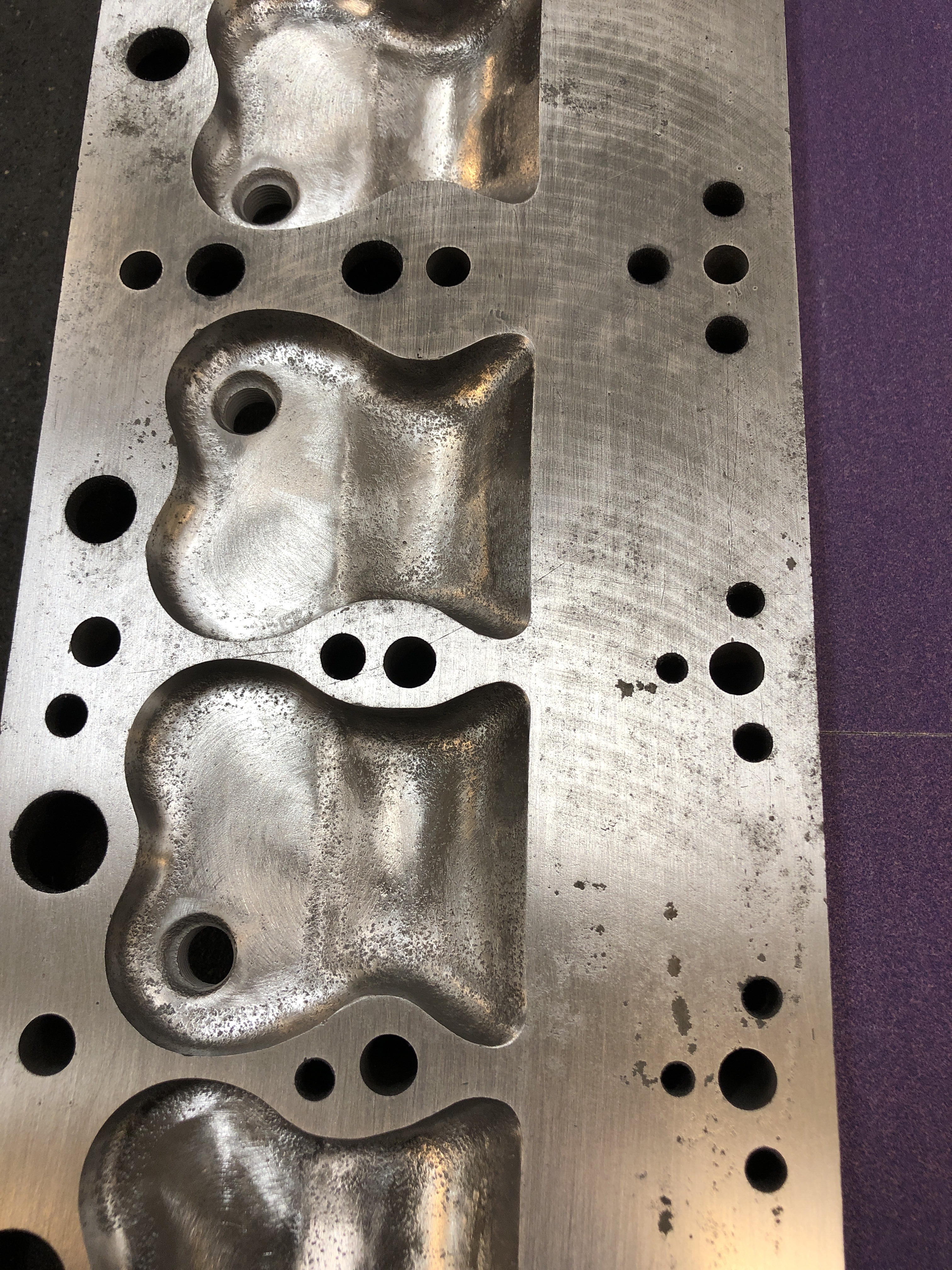

I’ve been giving my 37 Hudson’s 6cyl replacement head a surfacing at home by hand on a very flat surface. So, I’m know ideally one should try to remove all the surface imperfections to achieve a good seal. However, I’m getting one hell of a workout so I need to ask how much of the surface imperfections are acceptable? Are there specific areas which are more critical than others? I’ve been using 120 grit sand paper, is this the right grit to give the correct surface roughness for the head gasket to adhear to? I’ve heard different gaskets require different surface roughness.

0

Comments

-

Hi BigSky _ do I know you ? Anyway I am no expert on your specific questions but am a retired machinist and would make some recommendations. Measure the head at each corner and several spots in middle length for thickness - use a micrometer or good dial indicator that measures to .001 - should not be much variation ( I don't know how much is too much - gasket can only make up for a certain irregularity.) Also with top of block clean, place head on it and see if it rocks side to side - slide a feeler gage in all around until you find the biggest gap - I would start with .003-.005 and hopefully not able to go bigger. I do have a very old speck sheet that may or may not be applicable. It lists checking flatness with straightedge (accurate) and feeler gages : "desirable .003-.005;

serviceable .007 and repair or replace .010. This is a general auto recommendation and not specific to Hudson. So looks to me you have done a fine cosmetic job but unknown how straight it is. Usually the head goes to a shop where it is

ground flat. Some one on the forum may also know what thickness is usable and how flat it can go. And if head gaskets wary in thickness. Did this make any sense. Gert Kristiansen

0 -

Gert, I had taken a micrometer to it earlier & as I’d been working on it as well & both before & after the block thickness was good. Not being able to find my feeler gauges I had a retired mechanic friend check the head this morning with his feeler gauges & to give me his assessment of the head surface. He checked it with an 0.003 gauge without issues & it was straight at every point & even between each cylinder. He didn’t find any issues with the surface blemishes & didn’t get a reading when mic’d either. So it looks like I am good to go with the replacement head.

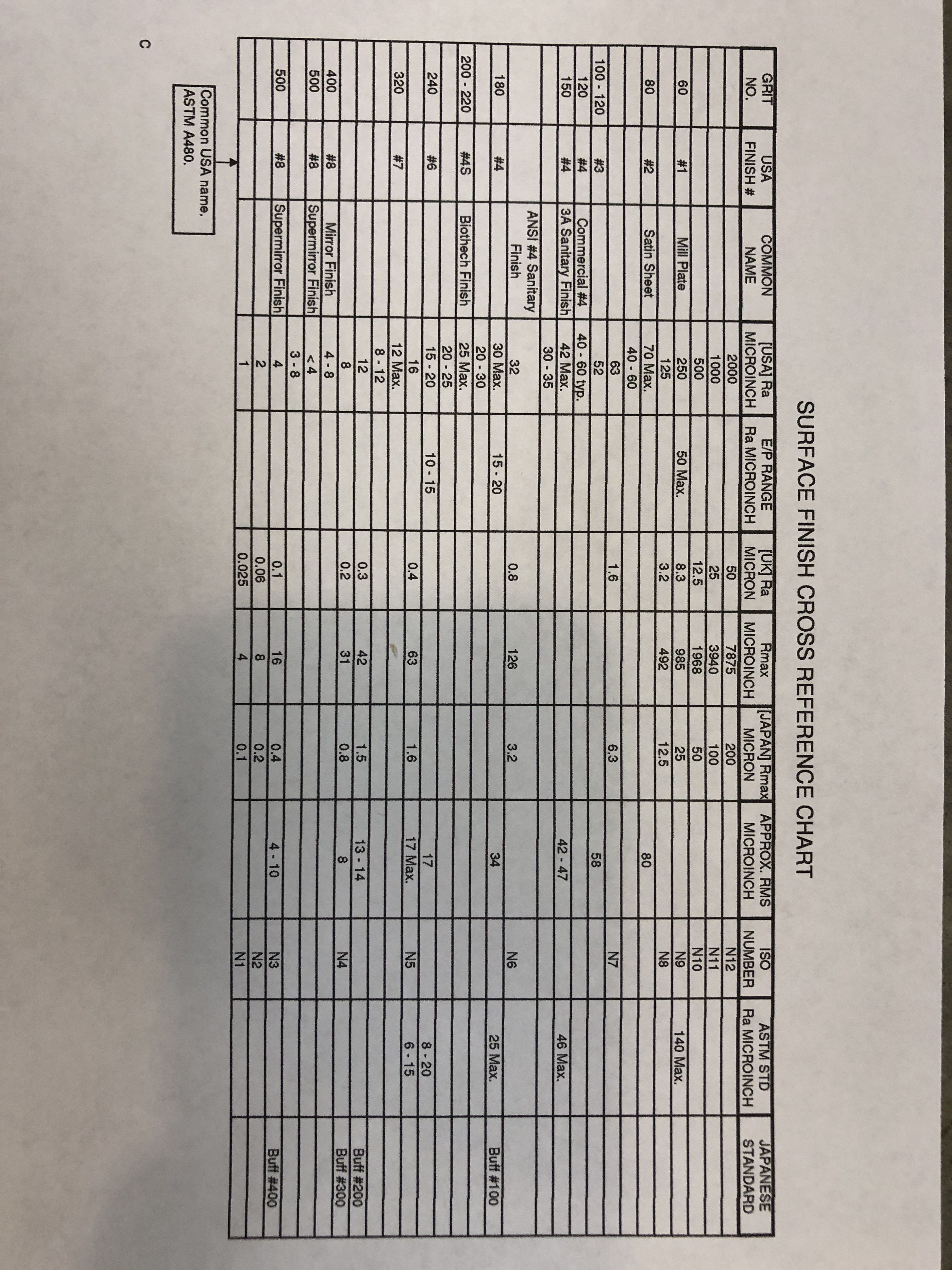

Further research this morning lead lead me to find the following “Surface Finish Cross Reference Chart. This chart had exactly what I was looking for; sandpaper grit number to Ra Microinch (Ra=roughness average). It has USA & UK Ra cross references as well.

I was also reading that a “traditional composition style soft-face head gasket on an engine with a cast iron head & block has a recommended 60-120 microinches Ra. Any idea if this sounds accurate for Hudson gaskets in the 37 Hudson I have with an iron block & head? My head gasket is from FelPro in the 50’s.

The article went on to say that on the same type of head gasket (traditional composition soft faced) on a cast iron block but with an aluminum head is smoother, 20-50 Ra. Would it be correct to assume that the aluminum head should have an Ra of 20-50 and the iron block of 60-120? Or should both the block & head be at 20-50 Ra?

0 -

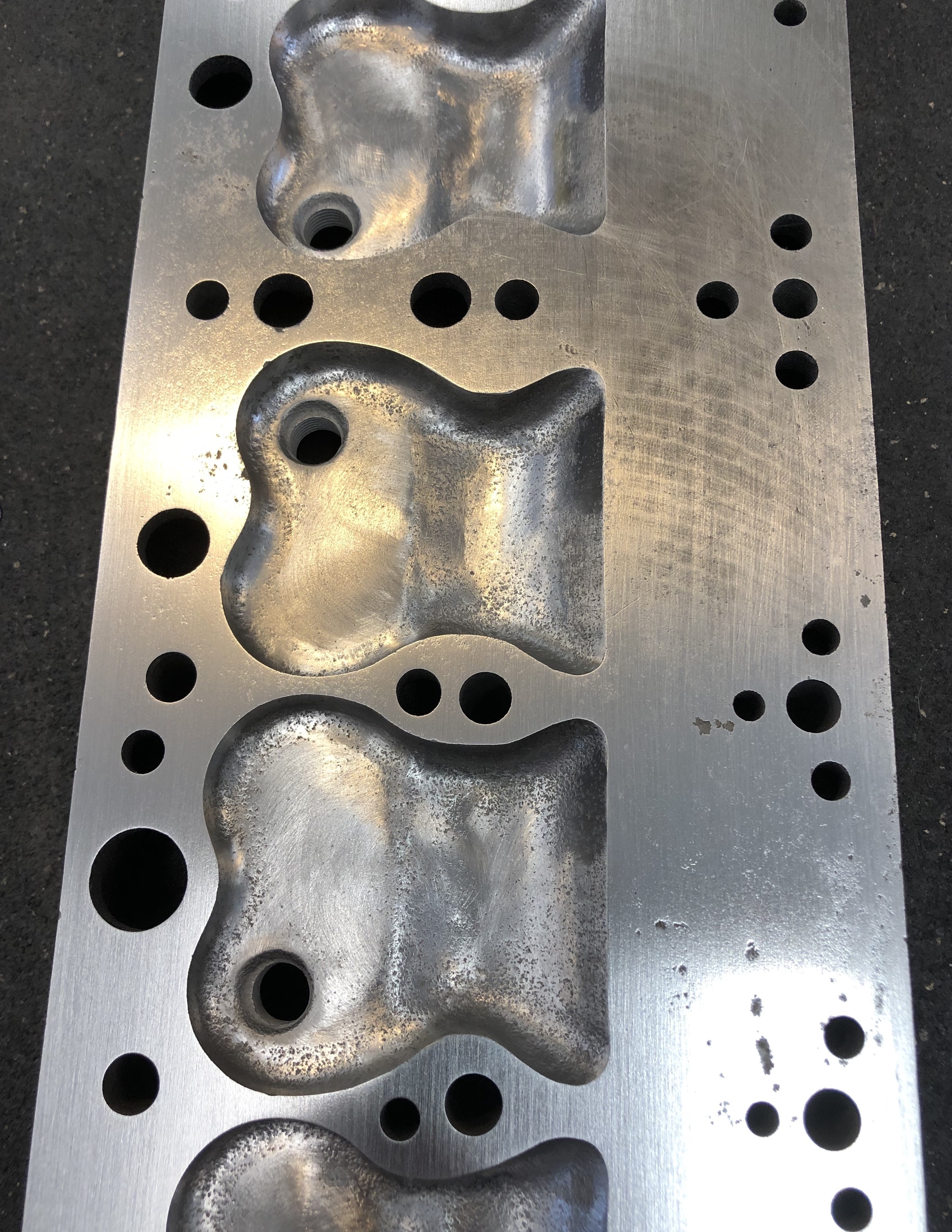

Hi there Bigsky did you get to a conclusion on calculating your compression ratio? The chambers on your head look shallow compared to what I remember a standard 212 head looks like the issue being if you put a 7.25:1 head off the small 175 engine on a 212 the compression ratio will be too high.0

-

I have 3 212's running those heads as well as a friend of mine and I do use premium fuel. you can really feel the difference when driving!

0 -

I haven’t done a CC measurement & calculation as of yet, it’s been difficult finding a syringe. If I only lived by the beach! ?

If I don’t find something this weekend I’ll order the Jegs $20 kit.

The original heads chamber does look close to twice as large, compared to this one so I will be doing a cc test to see the difference, to calculate the compression ratio of the replacement head and to make sure each chambers cc’s are the same so she runs smooth.

The retired SAE Mechanic friend of mine told me he & a few friends of his have done this exact head change in the past without issue. Granted he said I will most likely need high octane gas & may have to retard the timing a bit. With that said, he also said it makes quite a noticeable improvement. Especially considering not only is the chamber much smaller but the stroke of the 212 engine is around 7/8” longer than the 175 engine.

0 -

7.25 on a 175 could be 8.78 on a 212 using the same 175 head, ie 21% more swept capacity squeezing into the same head volume. That sounds very high? It'll be interesting as I thought 7.3 or so was enough for my 212 using the 112 head. I wonder how much load the centre main can take. Recall Brough supercharged the 212 which pumped out 140hp, however there's nothing I've ever read that says how long it held together. Someone must have some info on this.0

-

Do you have a profilometer to measure the Ra & Rz?

0 -

I’ve got the profilofinger to measuring the Rf & Lf, right finger & left finger! ?

Unfortunately I don’t have such a tool as I’m a shade tree mechanic, ok I’ve never heard of such a thing either. Is it critical on this old engine? I planned to check the cc’s on each head but that’s about all that I can do. I wish I could do more and actually machine these chambers to a specific shape, ideally improving things. I noticed some differences when I placed the head gasket on the head. Yet I didn’t want to mess around trying to fix it & make it worse.

0 -

If it aint broke, don't fix it!0

Categories

- 36.6K All Categories

- 85 Hudson 1916 - 1929

- 11 Upcoming Events

- 73 Essex Super 6

- 28.3K HUDSON

- 511 "How To" - Skills, mechanical and other wise

- 989 Street Rods

- 150 American Motors

- 170 The Flathead Forum

- 47 Manuals, etc,.

- 71 Hudson 8

- 40 FORUM - Instructions and Tips on using the forum

- 2.7K CLASSIFIEDS

- 592 Vehicles

- 2.1K Parts & Pieces

- 76 Literature & Memorabilia

- Hudson 1916 - 1929 Yahoo Groups Archived Photos