8 cylinder engine Problems and more woes.

pmlmbigpondcom

Expert Adviser

in HUDSON

G'day all,

The long running saga of the engine in our Railton is now at the stage that I have engaged a third engine builder. The first two could not get it right.

The first engine man, apart from forgetting to install the upper dipper sump tray ( I discovered before start up ) fitted oversize oil rings and gave the pistons only one thousandth of an inch clearance, the whole engine was fighting itself.

We stripped it down and found piston aluminium through the white metal bearings. the bores were also tapered, out of round by up to 6 thou and had chatter marks. Got almost all of my $$ back.

The next engine builder returned my engine to me many months and dollars later and it lasted 20 miles before No 02 big end decided to give itself an eighth inch clearance. Back to the engine man. bearings increased from 1 to 2 thou.

The rebuilt engine then did 1500 miles before it started to overheat. stripped down and discovered cracks to stud holes adjacent No 04 cylinder. Also found bearings by second engine man now failing, cracks and drag marks despite 2 thou clearance to journals. Also discovered that the second engine man did not clean up the bores from first persons efforts, Now none are both round and parallel, up to 5 thou out of round and others which are close to circular are similar amount tapered.

So it's now with another engine person who will totally rebuild on another block i have, provided it passes crack test. I am surprised at number and extent of cracks now visible after only 1500 miles ( that is of course if second man did actually do crack testing which I was charged for ) Sad part is that in neither case did i put a limit on costs and accepted all the suggestions ( and extra cost ) offered.

Now..........A number of questions

1) How common are cracks in 8 cyl blocks ?

2) What comments on white metal exhibiting shown symptoms

3) with 2 thou clearance to rods etc, what side clearance should be used. It seems that oil is not getting in / out of bearings

4) Camshafts has anyone used cams with improved timing for more power / if so I would appreciate details

Thanks

Phil

ms

ms

The long running saga of the engine in our Railton is now at the stage that I have engaged a third engine builder. The first two could not get it right.

The first engine man, apart from forgetting to install the upper dipper sump tray ( I discovered before start up ) fitted oversize oil rings and gave the pistons only one thousandth of an inch clearance, the whole engine was fighting itself.

We stripped it down and found piston aluminium through the white metal bearings. the bores were also tapered, out of round by up to 6 thou and had chatter marks. Got almost all of my $$ back.

The next engine builder returned my engine to me many months and dollars later and it lasted 20 miles before No 02 big end decided to give itself an eighth inch clearance. Back to the engine man. bearings increased from 1 to 2 thou.

The rebuilt engine then did 1500 miles before it started to overheat. stripped down and discovered cracks to stud holes adjacent No 04 cylinder. Also found bearings by second engine man now failing, cracks and drag marks despite 2 thou clearance to journals. Also discovered that the second engine man did not clean up the bores from first persons efforts, Now none are both round and parallel, up to 5 thou out of round and others which are close to circular are similar amount tapered.

So it's now with another engine person who will totally rebuild on another block i have, provided it passes crack test. I am surprised at number and extent of cracks now visible after only 1500 miles ( that is of course if second man did actually do crack testing which I was charged for ) Sad part is that in neither case did i put a limit on costs and accepted all the suggestions ( and extra cost ) offered.

Now..........A number of questions

1) How common are cracks in 8 cyl blocks ?

2) What comments on white metal exhibiting shown symptoms

3) with 2 thou clearance to rods etc, what side clearance should be used. It seems that oil is not getting in / out of bearings

4) Camshafts has anyone used cams with improved timing for more power / if so I would appreciate details

Thanks

Phil

ms

ms

0

Comments

-

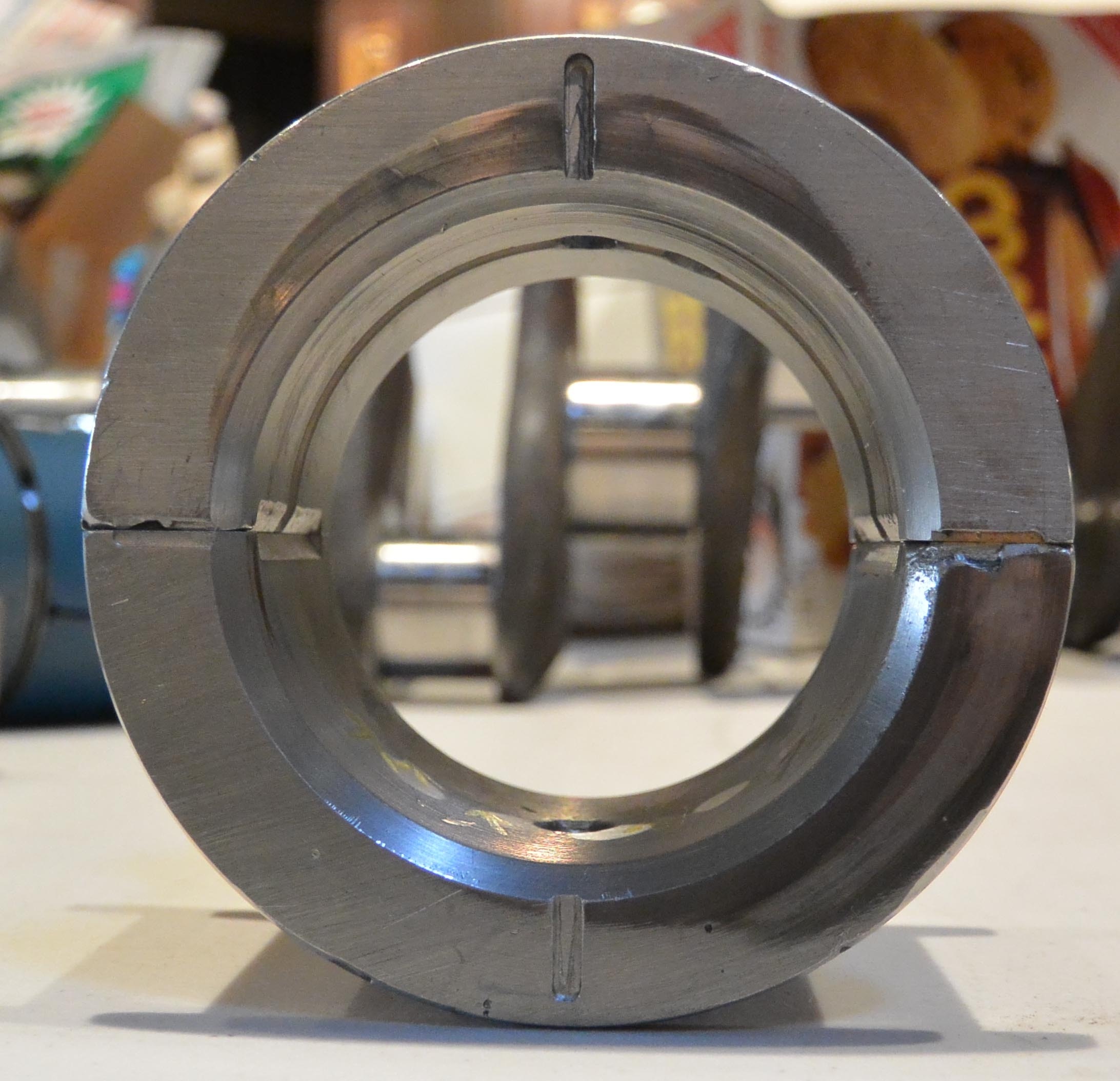

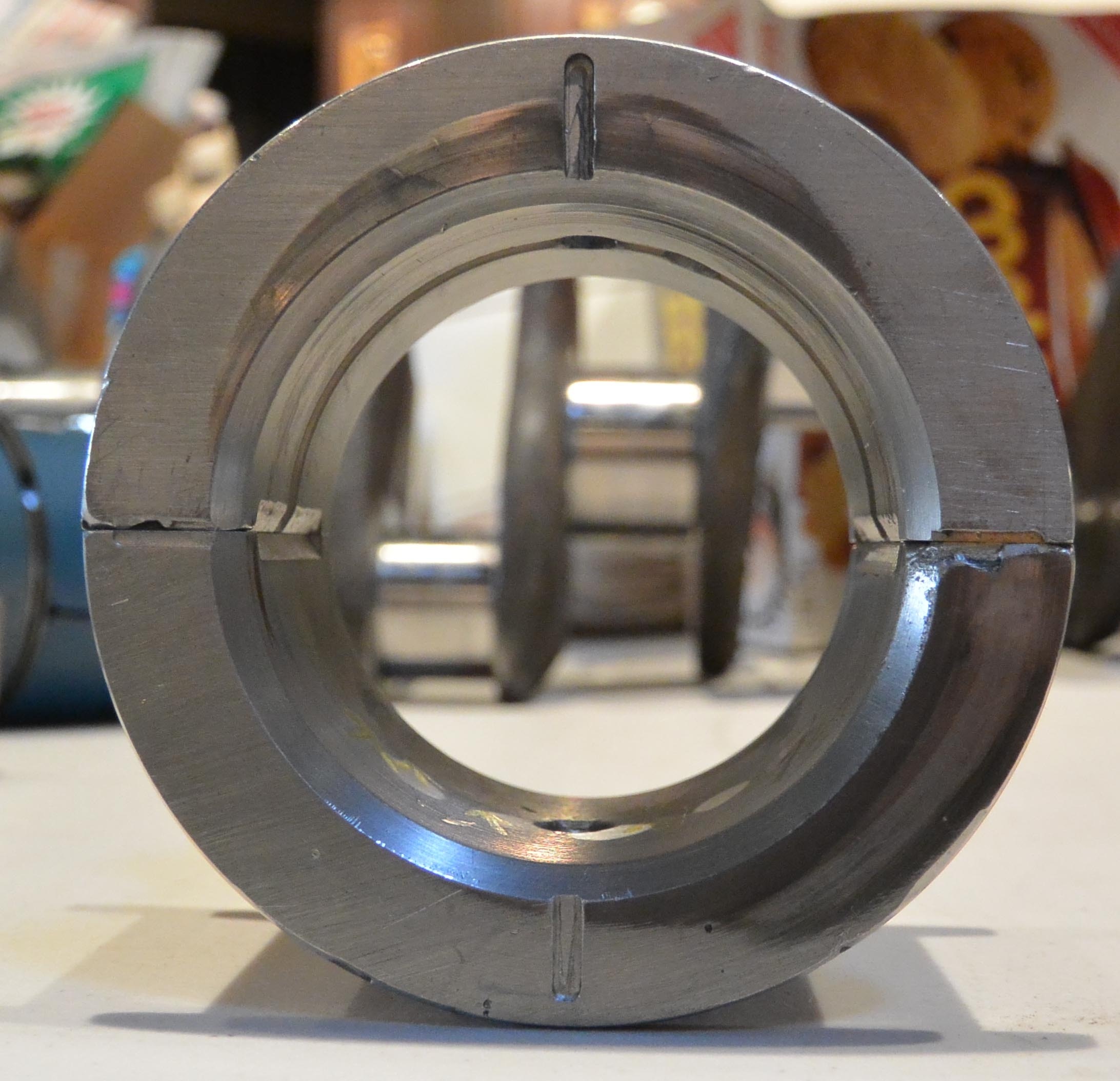

Several things - your block has been bored out and sleeved. This boring out has weakened the block, leaving it without the structural integrity to take the strain of tightening the head down. I'm afraid this will be a write-off. My recommendation, if sleeving is to go down a size, to either 2-7/8 or 2-15/16, which will leave enough metal for the block to take a few strains. The connect rod bearings have a groove right around, and a solid shim. This does not permit the oil to circulate enough for adequate cooling, hence overheating and fretting. Likewise the main bearings. There must be a good flow of oil through the bearings, the more the better. The con rods should have a good wide groove in the bottom half only, right around the half circle, and a good gap between the shims and the journal for the oil to freely circulate. The main bearings should have a groove in the top half only, and likewise a good gap for the oil to flow out the sides. 1 to 1.5" clearance is adequate clearance for all bearings and pistons.

This is how I have always set H8 and 6 motors up, and I have not had any failures, apart from sleeved motors doing exactly what yours has done. Careful running in for at least 500 miles is recommended, with 20 grade oil. This is not the first time I have come across so-called "experts" getting it wrong.

Geoff0 -

G'day Geoff

Yes, already about to deliver a non sleeved 10 thou over block to engine man

What side clearance should there be on big end journals / bearings ?

Thx

phil0 -

.005 - .010 is acceptable for side thrust0

-

Hello All and particularly Geoff C

My engine is progressing slowly but at least everything is being done to the best available standards.

Geoff, you mentioned he grooves in the white metal bearings, what size should they be? Width and depth in each case.

Also how far back from the face of the white metal would the shim sit ?

Anyone else with experience may comment and I would welcome same.

Thanks

Phil Macwhirter

Australia0 -

The groove must be in the cap only, not the rod, and be at least 3/16" wide and 1/16" deep. The shims should set back from the journal around .015-.025" to give the oil free passage through the bearing. You must have good oil circulation through the bearing to keep it cool. .0015" is the recommended clearance for a splash fed bearing. Also recommended good running-in oil around 20 S.A.E.0

-

Thanks Geoff

Presume the same sized grooves in the main caps

phil0 -

Even wider in the mains, but the groove goes in the top shell only.0

-

Thanks again

Phil0

Categories

- 36.6K All Categories

- 85 Hudson 1916 - 1929

- 11 Upcoming Events

- 73 Essex Super 6

- 28.4K HUDSON

- 511 "How To" - Skills, mechanical and other wise

- 990 Street Rods

- 150 American Motors

- 170 The Flathead Forum

- 47 Manuals, etc,.

- 71 Hudson 8

- 40 FORUM - Instructions and Tips on using the forum

- 2.7K CLASSIFIEDS

- 592 Vehicles

- 2.1K Parts & Pieces

- 76 Literature & Memorabilia

- Hudson 1916 - 1929 Yahoo Groups Archived Photos