Differential & rear wheel bearing question on 35 Terraplane

35 Terraplane

Senior Contributor

in HUDSON

Hi All,

So the differential on my 35 Terraplane has one pipe plug in it that I can see.

I read one sentence in the lubrication section of the Procedure Manual that says to "drain & flush the unit".

I take it that to change the gear oil you remove the plug and have to suck the old gear oil out with a vacuum pump?

Any ideas on how to flush the differential and what the flushing fluid may be?

I assume that you'd then fill it to the level of the plug hole?

Also when I was under the car I see that one right rear wheel is showing signs of a oil leak.

A few questions on this.

In the Master Chassis Parts book it shows item "B6-6 Drive shaft felt washer and retainer assembly" on the inner side of the wheel bearing and item "B7-3 Wheel bearing adjusting cap oil seal" outside the wheel bearing.

Is it possible to blow the inner B6-6 felt washer seal out by pumping to much grease into the zerk at the outer end of the axle?

OR Is it possible to blow both the inner B6-6 felt washer and outer B7-3 oi seals out by pumping to much grease into the zerk at the outer end of the axle?

I assume the latter as I have something leaking into the wheel drum.

I'd found rear wheel bearings back in 2015 so I'm all set there.

Actually sold several sets to other club members both here in the States & Australia.

I'd like help with finding both the inner felt seals and outer oil seals if anyone has manufacturer & part numbers.

If the dimensions are know I have an old Chicago Rawhide catalog that may be useful in finding a like kind.

I'm also looking for any guidance in tackling these jobs.

Thanks and Regards,

Tom

So the differential on my 35 Terraplane has one pipe plug in it that I can see.

I read one sentence in the lubrication section of the Procedure Manual that says to "drain & flush the unit".

I take it that to change the gear oil you remove the plug and have to suck the old gear oil out with a vacuum pump?

Any ideas on how to flush the differential and what the flushing fluid may be?

I assume that you'd then fill it to the level of the plug hole?

Also when I was under the car I see that one right rear wheel is showing signs of a oil leak.

A few questions on this.

In the Master Chassis Parts book it shows item "B6-6 Drive shaft felt washer and retainer assembly" on the inner side of the wheel bearing and item "B7-3 Wheel bearing adjusting cap oil seal" outside the wheel bearing.

Is it possible to blow the inner B6-6 felt washer seal out by pumping to much grease into the zerk at the outer end of the axle?

OR Is it possible to blow both the inner B6-6 felt washer and outer B7-3 oi seals out by pumping to much grease into the zerk at the outer end of the axle?

I assume the latter as I have something leaking into the wheel drum.

I'd found rear wheel bearings back in 2015 so I'm all set there.

Actually sold several sets to other club members both here in the States & Australia.

I'd like help with finding both the inner felt seals and outer oil seals if anyone has manufacturer & part numbers.

If the dimensions are know I have an old Chicago Rawhide catalog that may be useful in finding a like kind.

I'm also looking for any guidance in tackling these jobs.

Thanks and Regards,

Tom

0

Comments

-

The only suggestion I can make re draining one of these diffs is to undo by one turn the nuts that hold the centre into the housing.

For flushing, fill the diff with diesel or thin engine oil or ATF whatever is cheap and lubricating. Jack one wheel just clear of the ground, put the car in first gear run the engine for 10 minutes. Drain and repeat as required.

Seals, the B6-6 inner seal keeps the diff oil in the diff, the B7-3 outer seal keeps the grease in the bearing and dirt out of the bearing. The inner seal is Hudson only and no longer available, I have a write up on here from a year or two ago on my version of a work around, there are others.

If you let bubba loose with the grease gun it is possible to blow seals.

0 -

In my opinion it is entirely unnecessary to drain and flush the diff, unless you have signs of filings or the oil has gone extremely black. My Jet has done over 300,000 miles and the rear end has never been flushed. And if you have ever dismantled a rear end, and seen the thick varnish coating the inside of the housing has, then you are asking for trouble if you are going to dislodge this and have it flinging around inside the bearings and gears. My two-bob's worth

Geoff

0 -

While you are doing the diff work, its probably not a bad idea to remove the centre and check the bolts that hold the crown wheel to the pinion, they are a known weak point, its not unknown for the bolts to shear. Its a design problem, probably not enough bolts to start with, but mainly the soft metal lock tabs under the bolt heads compress over time. The bolts lose their tension and no longer securely clamp the CW to the carrier.

That's why Hudson changed from a 6 bolt crown wheel to an 8 bolt crown wheel in I think 38 and charged the method of securing the CW bolts.

To illustrate, I dismantled a 34/5/6 diff a while ago, and on first appearance everything looked fine, the crown wheel bolt lock tabs were in place. When I undid the CW bolts they had very little torque on them and looking at the mating surfaces of the CW and the carrier I could see where one had been moving against the other.

Looking at the bolts they all had a shiny surface on one side where the CW had been bearing against them, the bolts had become little more than drive pegs.

Nowadays we have wonderful things like loctite to help in these situations. And some new grade 8 bolts of course.0 -

Thanks Bob for the head up. I wasn't planning on going that far but one thing always leads to another. My car has 31325 original miles on it so I may not tackle that job until I do more reading in the Procedure Manual and muster up the courage to attempt it.

I test fit this puller that I bought a few years ago from another club member. What do you think. I looks like it may have been intended for a hub with a bigger bolt pattern. The feet don't sit quite flush on the drum. I take it you want the bolts as tight as you can get them. I'm nervous about torquing the bolts and bending them.

Mike Schlepp "farmermike" had replied to my wheel bearing post of a few years ago with a part number form the outer seal as SKP 17124. I searched the web and got some hits on SKF 17124 and found a cross reference to the Chicago Rawride part number. I checked my old catalog today. Both listed the identical dimensions and list the material as leather. I'm thinking once I get the Wheel Bearing Adjusting Cap Assembly off I'd check the dimensions so see if this is indeed the correct seal.

And Yes, I do have a jack stand under the axle that you can't see in the pictures.

0 -

The bolts into the drums don't need to be tight, they just need to be well engaged and sticking out from the drum equal amounts. The drums can be very tight and come off with force when they let go, leave the axle nut on loose as a safety.

Don't hammer the end of the puller shaft.

If the car is mobile, another method of loosening the drums is to undo the axle nut 2 threads, put the split pin back in and go for a drive.

Don't hammer the end of the puller shaft.

You will find shims under the bearing caps, the caps and shims need to go back on the side they came from.

Don't hammer the end of the puller shaft.

0 -

Got the Drum off. It took few days. As many have said, a little penetrating oil multiple times, lite tapping on the OD perimeter of the drum, a few strikes on the dog bone of the puller each morning and evening and this afternoon bang, off she came. The drum looks to be in very good condition with no groove cut from the pads over time. The outer seal looks like toast as far as I can tell without taking the cap ass'y off yet.

I read there should be .004 to .010 end play. It appears there is no end play at all at this point.

Section 13, page 6, figure 1307 of the manual shows the tool for removing the axle and wheel bearings. It appears to be a slide hammer threaded onto the the axle threaded end.

Is this correct? If yes, I think I can fab one of these up.

There is also a callout it the text on page 6 for bearing remover J-358.

Does anyone have one of these that can can post pictures of and an explanation of its use.

Thanks for now

Tom

0 -

Another method of removing the axle is to put a short length of pipe and a washer over the axle then screw the axle nut back on. The special seal puller is not really required.0

-

Thanks Bob. I have some ideas to work with now.

I'll post more as I go along.

Regards,

Tom

0 -

I have an old flywheel which I use ,put the flywheel over the shaft,replace the nut give it a pull and bingo,away the axle comes,they usually are not tight.0

-

Should the axle chuck in and out the at this point.? Manual says .004 to .010 but it appears not move at all.

Bob,

Are the bolts you said to replace #7 in the attached axle figure 1301?

Tom

0 -

Yes, it will be obvious once you see them. The replacement bolts do need to have a full diameter shank where they go through the crown wheel. You will probably have to buy grade 8 bolts with a suitable shank length and shorten them.

3/8" x 24 from memory.0 -

Tom, here's a simple way to do it. The plate is about 3/8" thick. Grade 8 bolts. Under the plate, on each bolt is a washer and a nut under it. Position the bolt heads on the axle flange area, one at a time, then, working one bolt then the other, hold the bolt head with a wrench and use a second wrench to turn the nut under the plate. It's a bit slow, but will pull the axle pretty easily.0

-

Made a slide hammer of sorts, but he weight on the little dent puller I have doesn't seem to have enough mass to move the axle. On to field revision "A".

Tom

0 -

Stiffened up the yoke.

With the 3/16 bent bail and the dent puller I could see the bail flexing.

Cobbed up a bigger slide hammer. Have been putting PB Blaster on the bearing seat right along..

Still took 10 or 12 good pops to get it out.

The bearing cone roller race is chucking slightly but maybe only a bit more than the new ones I have. The cup has a few marks on it but overall not bad.

Threads look good. Looks like the flat spot has been there since the day the keyway was cut.

Now the part that makes me nervous.

The splines look good but the button on the end appears worn.

As I mention previously there was no end play in the axle when I got the drum off.

I've seen in other posts about the button being damaged by being too tight and the damage it can do to I believe the pinion in the differential.

Can anyone chime in on this and give an assessment of the buttons condition and if I'm correct with it damaging the pinion.

On the inner side of the bearing where the seal runs on the shaft has a polished spot.

I checked it with my gunk verniers. The polished spot was only about .001 smaller than on either side of it. I'll have to bring my good ones home.

Found some original inner & outer leather seals. Hoping for the beat with these.

The axle housing looks OK. Some marking but almost looks like tool marks from when it was originally machined.

Any feedback would be greatly appreciated.

Tom

0 -

It all looks fine to me. The polished centre part of the thrust button is where the contact is.0

-

Those end thrust buttons look fine, end play in the axles should only be .004". The buttons bear on a hardened thrust block, even with zero end play there will be no effect on the pinion.

If you have negative end play, i.e. not enough shims in the shim pack you are effectively preloading the wheel bearings.0 -

Thanks Geoff & Bob,

I'm much relieved about the axle button.

I have a few more questions.

Should I dress the end of the button with fine emery cloth?

I also have questions on the attached PFD about reassembly of the axle & bearing to attain the .004 to .010 end play.

Tom

0 -

If you have not altered anything, and there was no end play before you dismantled the assembly, then just bolt everything back together again.0

-

The shim packs locate the bearing cups, the bearing cups need to be positioned such that the assembly of the 2 axles and the thrust block (consider that assembly as a solid rod if you like) have no more than the specified amount of end play. The movement is from the cones moving in and out of the cups.

RANT ON. From a purity of design point of view, i.e. avoiding steps in shafts, the Hudson tapered bearing seat is an excellent design. From a real world service point of view the design is a PITA - see below. Much better to have a parallel seat and slide the bearing up to a shoulder, most car manufacturers figured this out. RANT OFF

The cones need to be located properly on the axle tapers. If they are on too hard there is a danger of splitting the race, if they aren't on hard enough they will move in the first mile or two and increase the end play you so carefully adjusted. There is a method in the manual for correctly fitting the cones to the shafts.

0 -

Cleaned the axle, cap etc. they all look very good.

I rechecked the polished spot on the axle and confirmed it is only .001 less than the shaft on either side of the polished spot.

0 -

Hi Everyone.

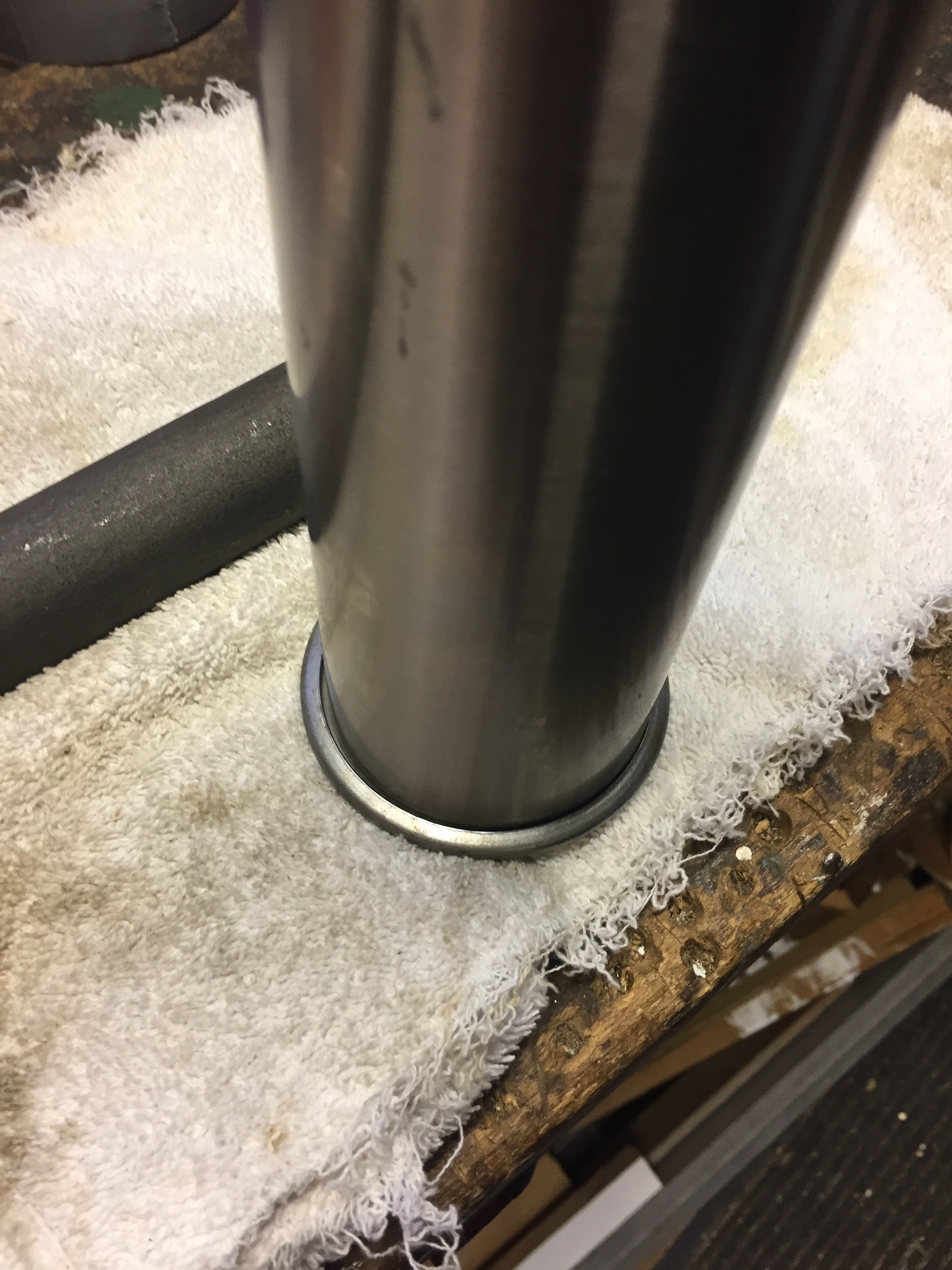

Only took a year to get back to this. Had a few things come up late last July into the fall. Anyway, installed the inner seal using a piece of 2" schedule #40 pipe. Worked well. Cleaned and packed the bearing. Installed the axle, wrapped the spline with a thin piece of plastic to protect the seal as I pushed in in. Lightly tapped in the bearing cup into the housing.

Question?? How to drive the bearing home. The manual says " assemble read wheel bearing outer cup" I'm nervous about getting it cocked and not driving it in straight. Can you use the outer adjusting cap to push the bearing cup in using longer bolts? Again, nervous about breaking off the ears on the adjusting cap.

Any advice is greatly appreciated.

Thanks and Regards,

Tom 0

0 -

Just gently tap it all round with a punch, and then finish off with the bearing cap to push it right into place.0

-

Thanks Geoff. I'll have a go at it.0

-

I just did this on my 48. The outer race (cup) fits pretty snugly into the housing. In order to check the end play, each time I added or removed a shim, I had to use my axle puller to gently tug the cup out to the retainer plate. Then I was able to check the end play. Without doing this, the end play may not become evident until you have driven the car for a while and the cup finds it's own position. Also, the block in the center of the diff, that the buttons push against, is sort of free floating. When you adjust the shims on one side, it also affects the end play on other side.0

-

One last Question.

When putting the brake drum back on can you / should you put a lite bit of grease or never seize on the taper of the axle?? OR just clean and dry??

As Always thanks for the help.

Tom0

Categories

- 36.6K All Categories

- 85 Hudson 1916 - 1929

- 11 Upcoming Events

- 73 Essex Super 6

- 28.3K HUDSON

- 511 "How To" - Skills, mechanical and other wise

- 989 Street Rods

- 150 American Motors

- 170 The Flathead Forum

- 47 Manuals, etc,.

- 71 Hudson 8

- 40 FORUM - Instructions and Tips on using the forum

- 2.7K CLASSIFIEDS

- 592 Vehicles

- 2.1K Parts & Pieces

- 76 Literature & Memorabilia

- Hudson 1916 - 1929 Yahoo Groups Archived Photos