Vibration Dampner - Is there a flat washer under the large bolt?

Hienkel429

Member

Hey all,

Is there supposed to be any washer(s) on the the large bolt that holds the vibration dampner/pulley on a 308 hornet? There wasn't one on it when I pulled it apart and wanted to make sure before I got it all put back together.

Thanks!

-Ray

0

Comments

-

All that I have had apart had a lock washer , using tabs to bend over the bolt head0

-

It's worth mentioning that the washer, whatever kind you use, should not tighten against the body of the dampener (the big, main part with the pulley groove)....only the hub part (with the key way). Maintaining separation of those two components with the rubber discs inside is what makes it a VD instead of just a hunk of iron.

F0 -

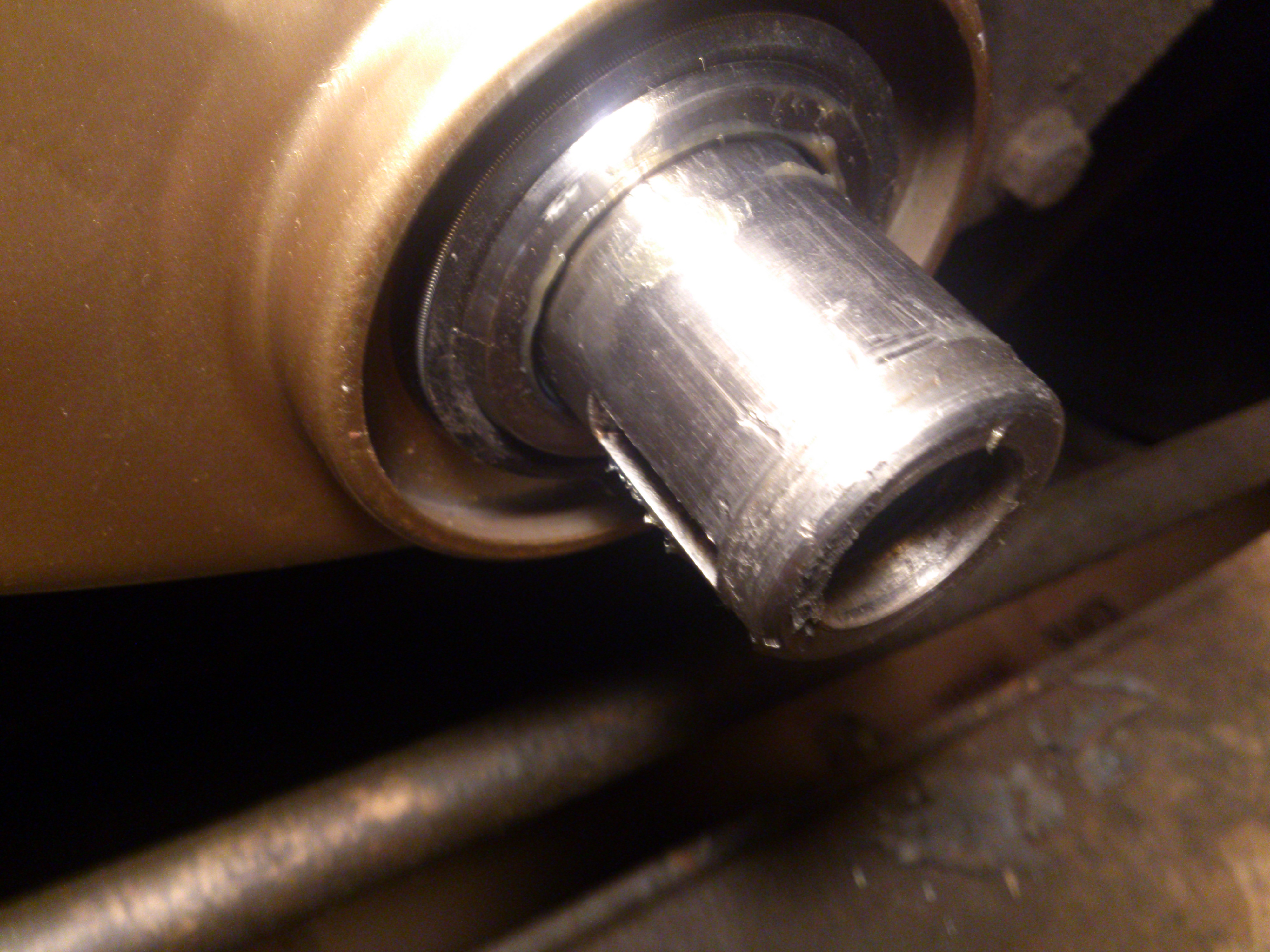

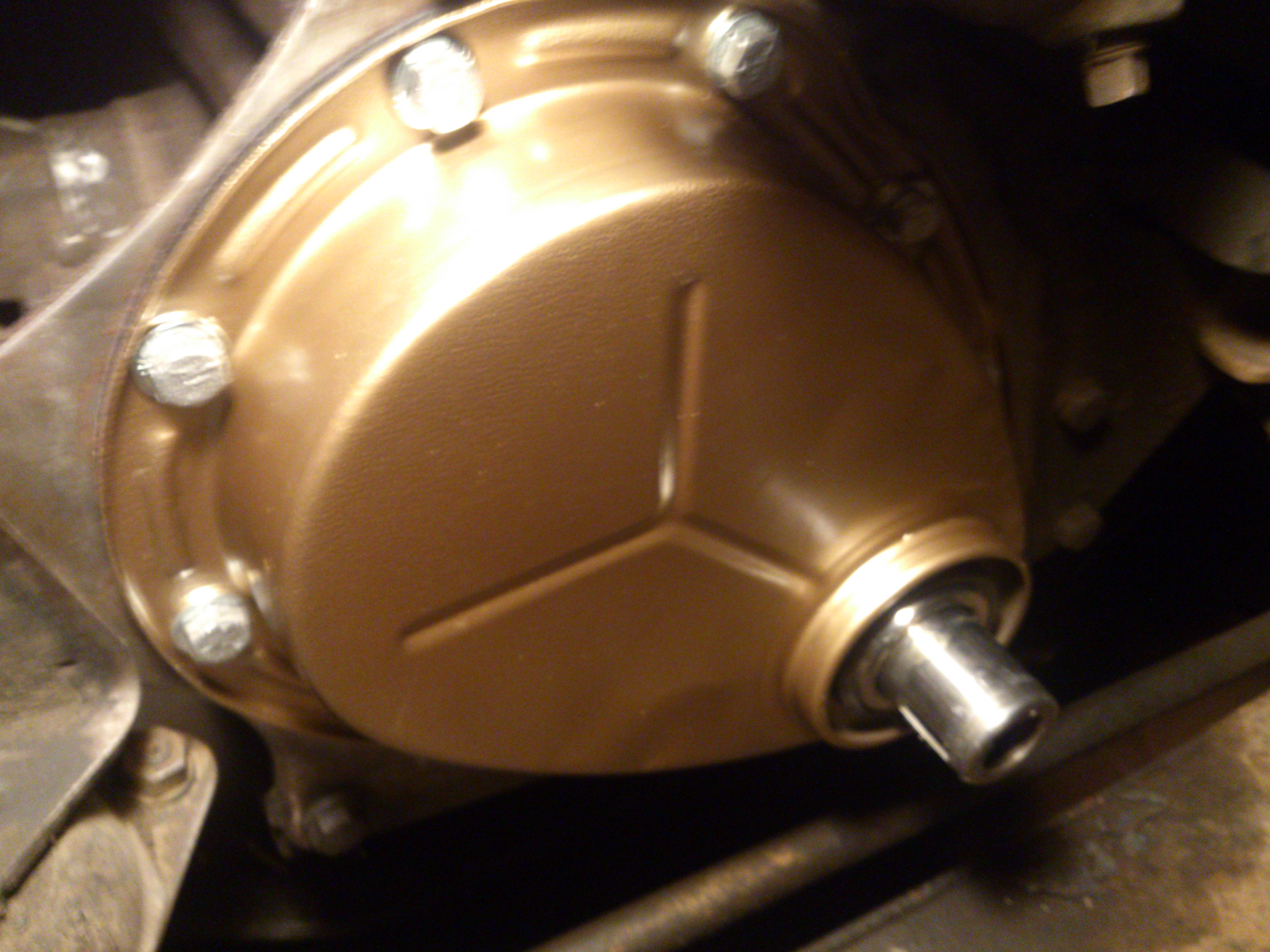

Thanks to who ever changed the title. A lot more descriptive!Ok the manual mentioned this washer so this is why I asked. Below are pictures of the bolt and all after I got the cover painted and replaced with a new seal. The Woodruff key is sitting on the dash and it is ready to go back in.

0

0 -

Here's my previous owners solution. He used two 1/8" thick washers and lock tab washer then drilled all three,countersunk the thin one slightly and installed a screw from the backside,peened it over flush on the lock tab and filed the screw head square to fit the balancer keyway. It served the 308 well and showed no distress on disassembly. Chrysler hemi and some Oldsmobile use the 3/4-16 size too so there are new balancer bolts available (minus the lock tabs) Balancer Bolt

I have no doubt that the anaerobic thread locking compounds available today are more than enough to keep that bolt tight and thats all I will be using on my build.

0 -

I hate to be the bearer of bad news,but you have that seal installed backwards...

0 -

I might send Doug an email. I know they were doing inventory this past week so might just wait to next week. If anyone has a spare they would be will to let go of, please let me know.Thanks- Ray0

-

@TwinH or anyone

Is the seal really on backwards? If so the person who last had this cover off did EVERYTHING wrong. I put the proper gasket on it, fixed the dents, fixed the retaining bolt wire, replaced the spacer, and put a new seal on it using the old one as a guide for direction. So the side with spring retainer goes on the interior of the cover? If so it definitely isn't bad news... much better to figure it now rather than later.-Ray0

Is the seal really on backwards? If so the person who last had this cover off did EVERYTHING wrong. I put the proper gasket on it, fixed the dents, fixed the retaining bolt wire, replaced the spacer, and put a new seal on it using the old one as a guide for direction. So the side with spring retainer goes on the interior of the cover? If so it definitely isn't bad news... much better to figure it now rather than later.-Ray0 -

Hey Ken,It is a new seal from Dale Cooper and I did use a new spacer. The other had a burr on the forward facing edge.- Ray0

-

Found my answer with a search. Everything is buttoned up and looks ALOT more correct.So... I owe alot of thank you's already, but one last question for when I get the correct washer.Does this dampner look ok?Thanks again to everyone for your help.- Ray0

-

-

I can see the assembly dots in your pic (frontside) and they're still lined up so good there. I just went out and checked my double pulley and the hub is .060" proud (sticking out further) than the pulley. I am just a little concerned about the witness mark on the pulley right next to the hub. Please lay a straight edge across the hub and combine some feeler gauges to measure the distance that the hub sticks out. And you are correct in that it is way better to find an issue now. The tech help on this forum has been a godsend to me and I've been building and wrenching on engines it seems like my whole life so don't feel bad. I made my living rebuilding aircraft engines but am still learning the quirks of these older automotive deals.

0 -

Also,since I don't have an original washer on mine I'm not sure,but,I would try to find one 1/4" thick. Others may advise what was originally there thickness wise.

0 -

You guys are awesome... let me go back out to the barn... will be back in a few...0

-

First up is the hub protrusion from the front of the pulley. This measured at .039. The hub seemed to be centered.Second is the hub protrusion on the back of the pulley. This measured at .229. More troubling is that the hub did not seem to be centered. On one side it was super snug against the back plate and on the other side I could easily fit a .04 feeler gauge. Is this anything to be worried about? I don't have a straight edge that small so I improvised with a door hinge. Everything appeared flat.Thanks again!-Ray

0

0 -

I'm going to guess that's probably within tolerance for a 60 yr. old harmonic balancer buts lets wait for more opinions. My biggest concern was that the bolt washer was not touching the pulley and I think .039" should work.

0 -

Ken,You're right. The "witness mark" is where I had taken a wire brush and began removing surface rust on the pulley.Thanks again everyone!0

-

Likely too late but I'm a fan of pushing the unit back on with a ball thrust-bearing as opposed to installation via a BFH (Big Frank's Hammer). Seeing VDs with the front face beat to hell is common and it certainly can't be good for the crank, considering the initial reaction to each blow is taken through the #1 rod throw.

F

0 -

Frank that looks like a great set up to work the VD on without brute force. Any idea of the type or size of the thrust bearing besides just 3/4?Thanks!-Ray0

-

Ray, The one in the photo came out of a ball bearing hook on a chain hoist (I think) but they are a common item. If you have an Applied Industrial Technologies around there it's p/n MA 0345900 (3/4 X ~1-1/2 X 9/16) with a dynamic load rating of 4250 lbs @ 5500 rpm (now that's high speed VD installation!) and static load of 7300 lbs. (much more meaningful). I'd guess about $25 (my catalog says 17 but it's a bit old).

There are a few other parts necessary to make it work (3/4 all-thread chunk, nut, washers) but they're just ordinary stuff.

F

0 -

A lot of power steering pulley kits have that type of bearing. Maybe check at Harbor Freight if you only intend to use it a couple of times.0

-

Guys, Autozone and others will loan you a FREE harmonic balancer installer that installs it smoothly and steadily with no hammering, etc. No need to buy tools or put together a bunch of washers. Usually there is a small deposit.0

-

Great Neck OEM 27144 Harmonic Balancer Installer

The above is the installer you can borrow from Autozone, $45 refundable deposit. Or you can buy it on Amazon for $40-50. It does have the proper adapter for Hudsons0 -

David...You're awesome! Those thrust bearings were impossible to come by locally. There is an autozone about 15 min. away.

Just need to find that washer... lolThanks-Ray0

Just need to find that washer... lolThanks-Ray0 -

Hey Ken,Sent him a PM a few hours ago. Just in case something cant be worked out, Denny at Wildrick says he has one as well.Thanks again... and for all the random stuff I will ask in the future...- Ray0

-

No problem, Ray. Love these loaner tools for rare jobs.0

-

Scottcrow22

Sent you a PM.

Lee O'Dell0

This discussion has been closed.

Categories

- 36.6K All Categories

- 85 Hudson 1916 - 1929

- 11 Upcoming Events

- 73 Essex Super 6

- 28.4K HUDSON

- 511 "How To" - Skills, mechanical and other wise

- 990 Street Rods

- 150 American Motors

- 170 The Flathead Forum

- 47 Manuals, etc,.

- 71 Hudson 8

- 40 FORUM - Instructions and Tips on using the forum

- 2.7K CLASSIFIEDS

- 592 Vehicles

- 2.1K Parts & Pieces

- 76 Literature & Memorabilia

- Hudson 1916 - 1929 Yahoo Groups Archived Photos